At Laboratory Testing Inc. (LTI), we are your dedicated support system throughout every stage of the metal production journey. Our commitment extends from the very inception of ingots, collaborating constructively with fully integrated metal producers and converters, and culminates in the delivery of top-quality mill products.

We specialize in a wide array of final products, including round and rectangular bars, seamless and welded tubes and pipes, sheet metal, plates, and precision forgings, all meticulously crafted for mission-critical applications.

With LTI, you have a partner who shares your dedication to excellence, ensuring your metals meet and exceed the most rigorous industry standards – from inception to final deployment.

We are metal experts in:

- Titanium and Titanium Alloys

- Nickel Alloys

- Stainless Steel

- Aluminum

- Steel Alloys

- Copper Alloys

- Additive Metals

- And more…

The LTI Advantage for Mills

Expertise and Industry Knowledge:

Leverage our decades of expertise in metal testing for mills. Our seasoned team understands the unique requirements of the metal production industry.

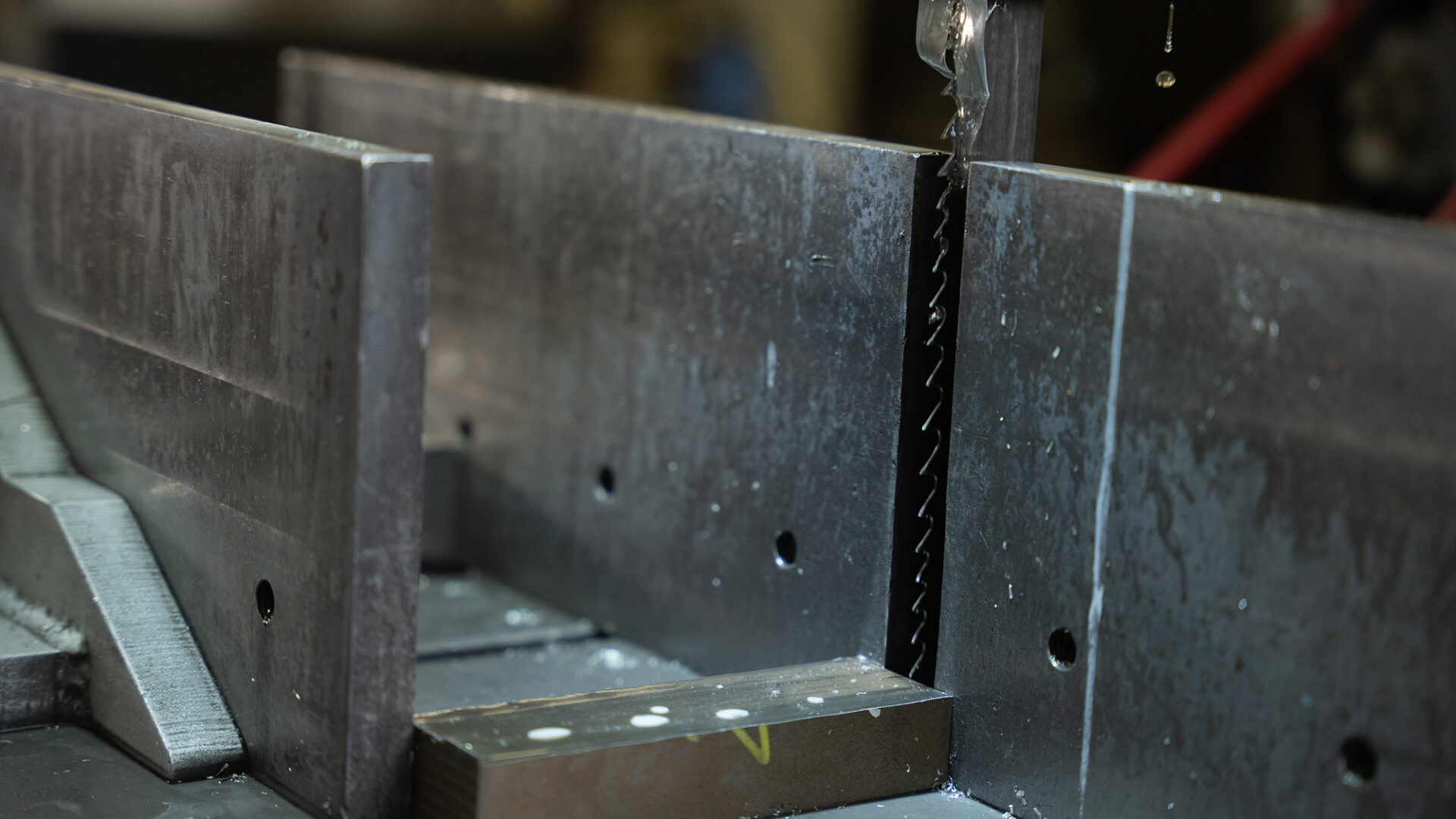

Comprehensive Testing Services:

From destructive to non-destructive testing, we offer a full spectrum of testing services to ensure the quality and integrity of your metals.

One-Stop Shop for Efficiency:

As a comprehensive testing facility, we streamline the process by offering a wide range of services under one roof, reducing transit time and costs. This convenience ensures you can efficiently manage your metal testing needs without unnecessary delays or logistical complexities.

Fast Turnaround:

Minimize production delays with our quick turnaround times. We understand the importance of timely results in the metal manufacturing process.

Industry Partnerships:

Benefit from our strong partnerships with industry leaders, ensuring access to the latest insights and advancements.

Seamless Customer Portal Access:

Our user-friendly customer portal provides 24/7 access to your test results, status updates, and historical data. Enjoy the convenience of tracking your projects and accessing reports at your convenience, enhancing transparency and efficiency in your metal testing process.

Services:

Nondestructive Testing

Both surface and internal flaws can be detected with our NDT test methods.

- Ultrasonic Testing

- Hydrostatic Testing

- Liquid Penetrant

Chemical Analysis

Utilize our test methods to confirm material chemistry, ensuring it meets specifications with precision.

- Atomic Emission Spectroscopy (AES)

- Combustion Analysis

- ICP Mass Spectrometry (ICP-MS)

Mechanical Testing

Testing is offered for the principal mechanical properties of interest to designers in the mill industry, including strength, ductility, and hardness.

- Tensile Testing

- Charpy Impact

- Bend Testing

- Fracture Toughness

- Fatigue Crack Growth

- Low and High-Cycle Fatigue

Metallurgical Testing

Physical characteristics of primary metal materials undergo thorough evaluation, with metallurgical examination techniques revealing and identifying defects or flaws.

- Microstructure

- Grain Size

- Macrostructure

Get in Touch

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.