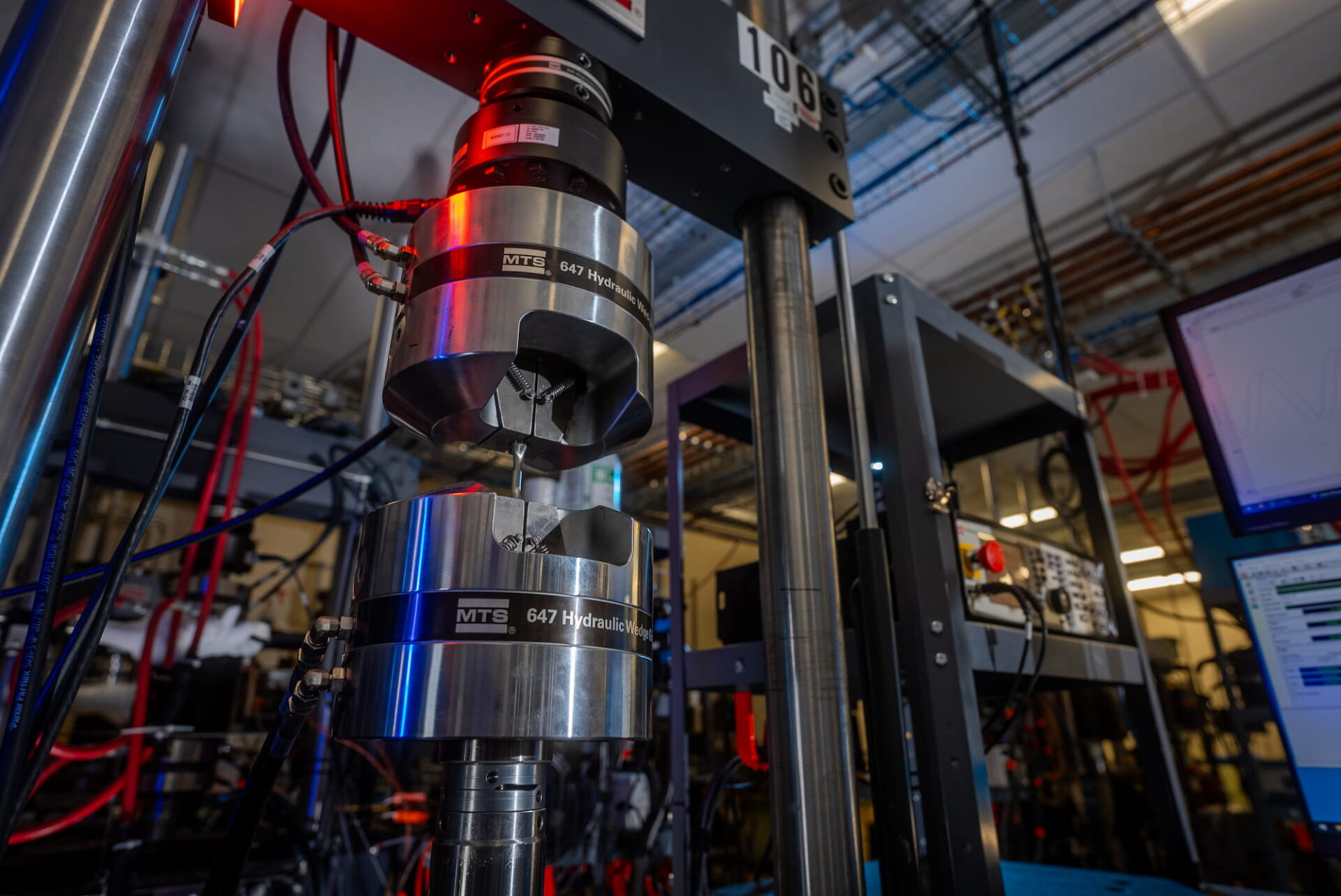

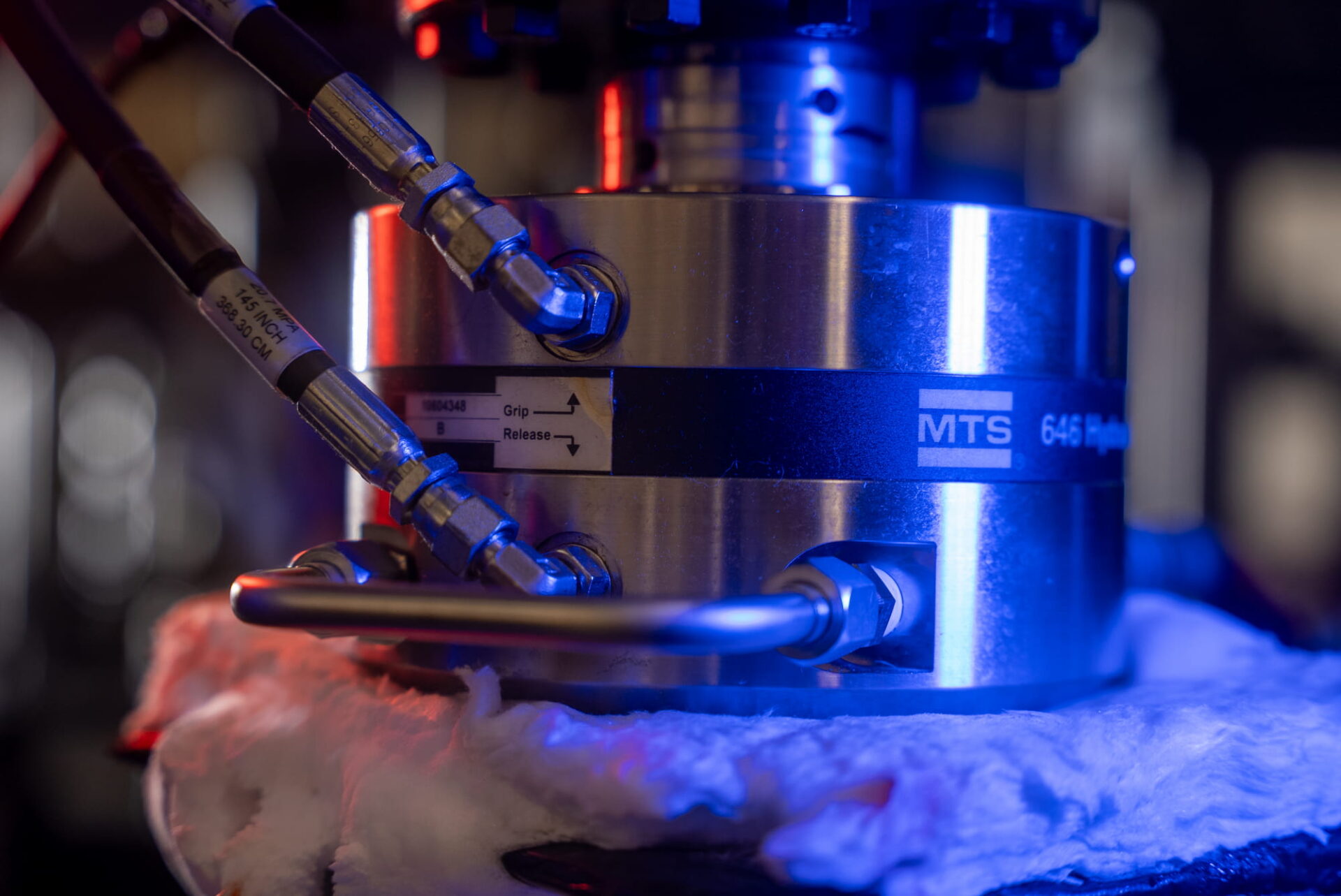

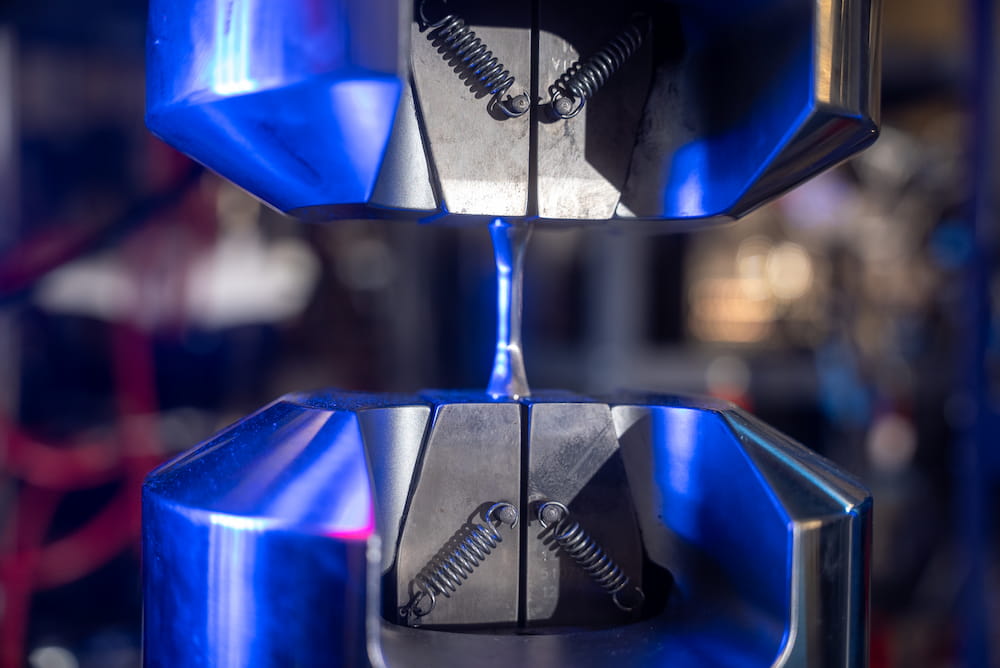

Laboratory Testing Inc. has the expertise to handle complex testing programs. Our engineers have decades of experience in fatigue crack growth testing across aerospace, power generation, and other key industries.

LTI has a full-service machine shop that supports the lab, with the capability to handle complex test programs – from extraction to large forgings and advanced specimen machining. Our state-of-the-art machine shop has low-stress grinding and polishing capabilities to create the finest specimens in the industry.

Our Project Engineer team supports our customers in this area. This group will be your point person for program management on our floor. They will provide weekly updates and a white-glove approach to your program to ensure we complete it accurately and on time.

Fatigue and Fracture Testing at LTI

Capabilities

Specifications

Fatigued by Material Testing Logistics? Try LTI

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.