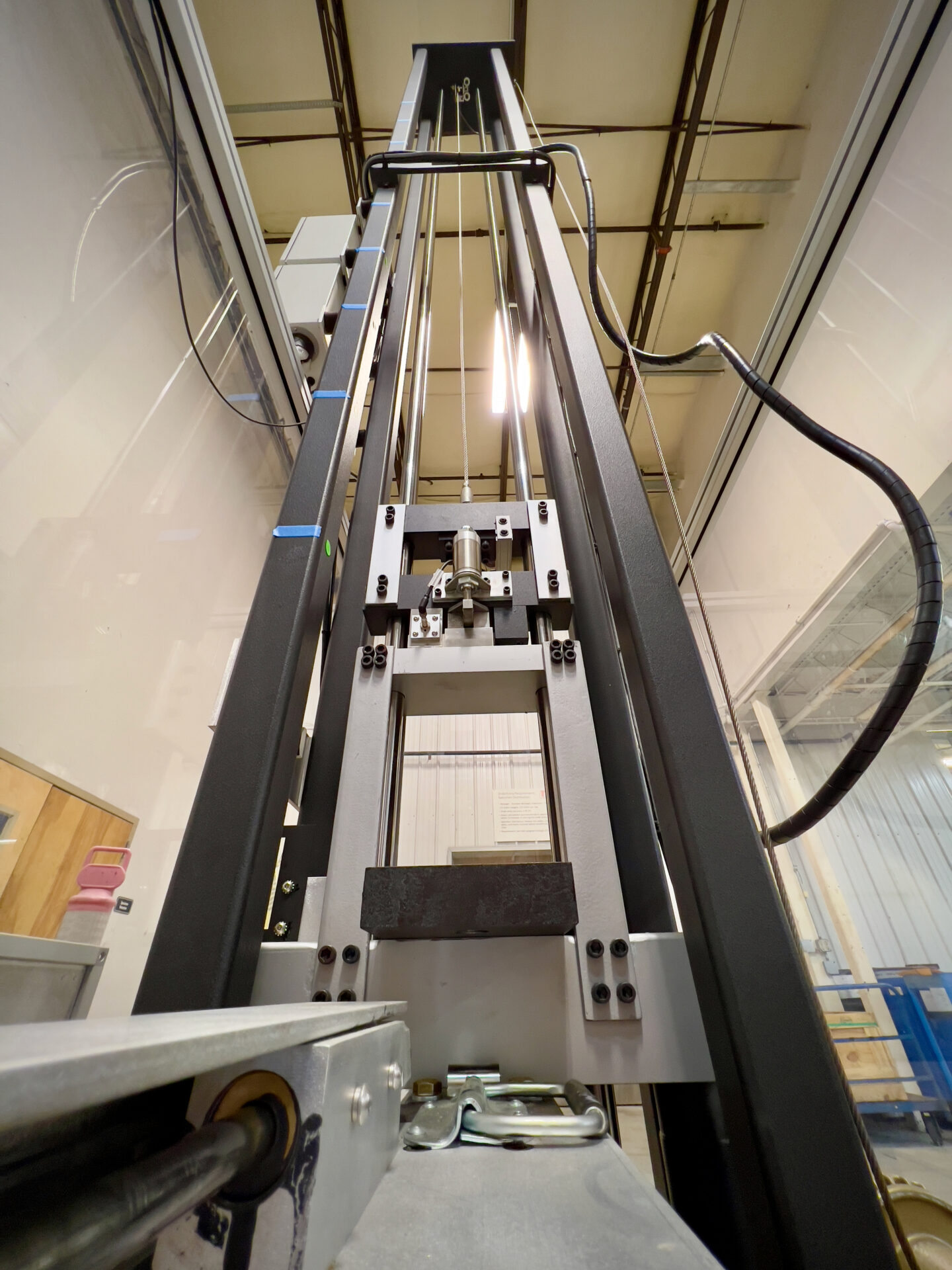

Laboratory Testing Inc.’s (LTI) Mechanical Testing Lab, located near Philadelphia, offers Dynamic Tear (DT) Testing, using repeated adjustable falling mass tests from varying heights. LTI’s new drop tower allows falls from adjustable heights up to 11 feet, with adjustable falling masses up to 4,000 ft-lb.

The DT test is performed at Lab temperatures or sub-ambient to -320ºF to uncover any effects on impact energy. These services provide test results that can be useful in assessing the suitability of a material for a specific application and predicting its expected service life.

What is Dynamic Tear (DT) Testing?

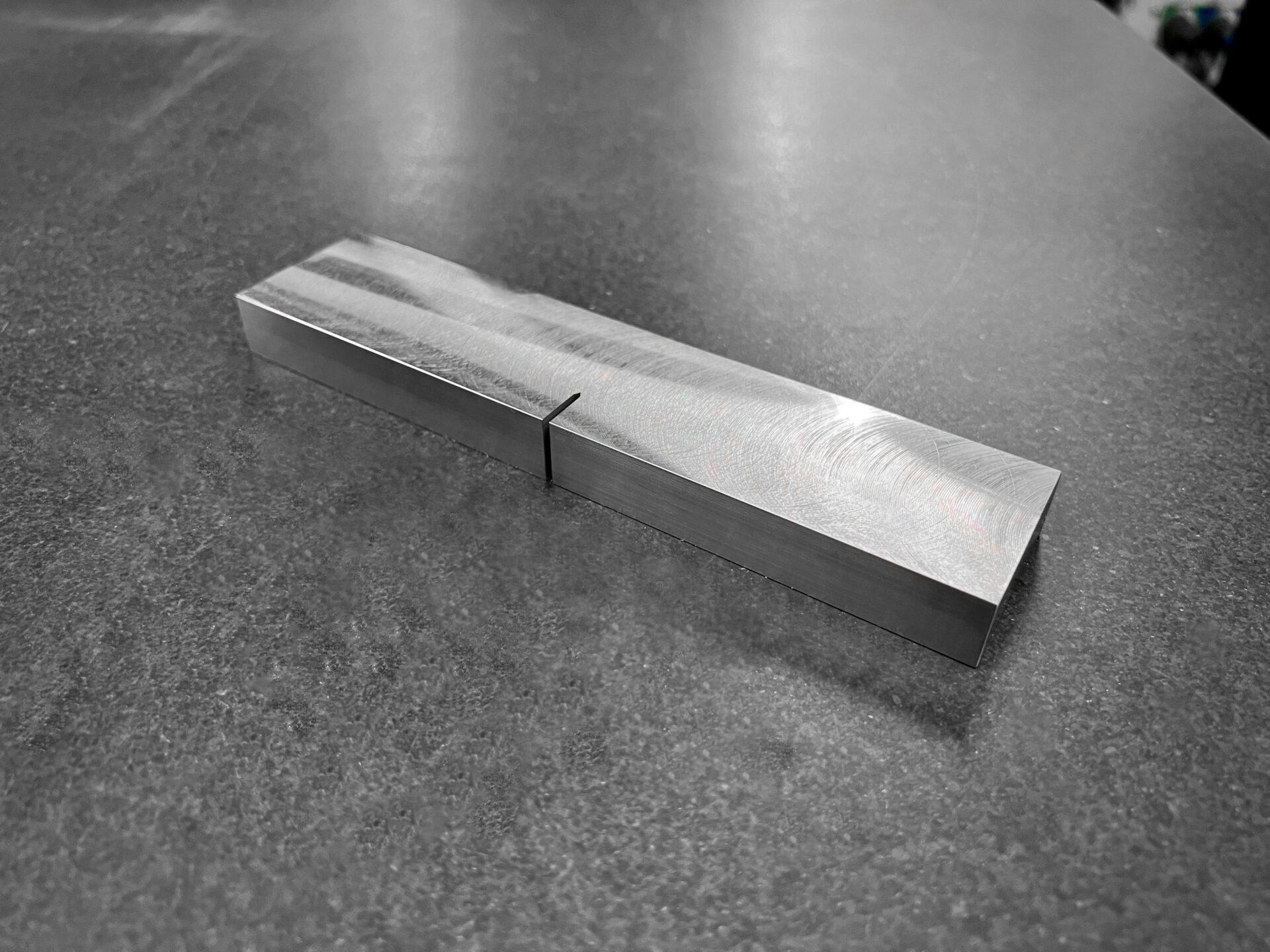

Dynamic Tear Testing is a method used to evaluate the resistance of metals to fracture under dynamic loading conditions. Originally developed by the U.S. Navy, it involves inducing a crack in a metal specimen and then subjecting it to rapid loading to propagate the crack. This helps determine the material’s resistance to crack propagation and fracture toughness under high-strain-rate conditions.

Applications of Dynamic Tear

Some applications of Dynamic Tear Testing include assessing the integrity of materials in aerospace components, pipelines, pressure vessels, and automotive structures. It’s particularly useful for scenarios involving sudden impact or dynamic loading, such as accidents or explosions.

Standards

ASTM Specification:

ASTM E604 Standard Test Method for Dynamic Tear Testing of Metallic Materials

Advantages of Dynamic Tear

Advantages of Dynamic Tear Testing include its ability to simulate real-world scenarios more accurately and provide insights into how materials behave under rapid loading conditions. This can help engineers design safer and more reliable structures, especially in industries where high-speed impacts or sudden forces are a concern.

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.