Customer expectations have heightened demands on manufacturing; products suitable for a wide latitude of environments and applications mean further constraints during production. Manufacturers must look closely at processes to gain extra performance wherever possible. Material advancements can’t come about without extensive testing to establish structure, quality, and purity. LTI’s chemical analysis lab assures manufacturers that their materials and resulting products meet all industry standards. An array of investigative analysis techniques and precision equipment also gives us a deeper insight into the performance of materials.

Capabilities

Let LTI Be Your First Stop for Chemical Lab Analysis

Chemical Analysis Lab Services

Atomic Emission Spectroscopy (AES)

AES analysis is one of the most useful analytical chemistry techniques for directly analyzing elemental composition in solid metal samples. LTI’s AES spectrometers can analyze all common elements in metal and alloy samples, including soft metals such as tin, lead, and zinc. Both qualitative and quantitative information are reportable.

Inductively-Coupled Plasma (ICP)

LTI performs ICP, atomic emission spectroscopy (AES), and mass spectrometry (MS) with fully computerized, top-of-the-line spectrometers. ICP-AES is a technique that detects most periodic table elements and determines trace elemental concentrations to major. Reliable results are attainable for about 70 elements with detection limits in the parts per billion range. The ICP-MS can evaluate a range of metals and several non-metals and is highly sensitive and capable of trace element analysis on multiple elements, often at the parts-per-trillion level.

Moisture Analysis

Moisture analysis reveals the moisture percentage in various inorganic materials, including welding flux, ores, ferroalloys, and chemical samples. The analyzer uses radio frequency to heat the sample to the specified temperature to separate the moisture from the rest of the sample. An infrared detection process quantifies the moisture in comparison to a reference material. Moisture reports indicate the reading as a percentage of the total weight. The analysis is valuable in preventing weld rejection due to porosity and informing material buyers about the percentage of weight attributed to moisture.

Positive Material Identification (PMI)

LTI performs PMI testing with a non-destructive technique called portable X-ray fluorescence spectroscopy: the equipment directly analyzes solid metal samples and thin metal films for major elements and can be used for screening of metallic and non-metallic samples.

Fourier Transform Infrared (FTIR) Spectroscopy

FTIR spectroscopy can identify organic, polymeric, and inorganic materials in solid, liquid, and powder samples. This method can assess purity, reveal the molecular structure of the sample, and identify additives, contaminants, and basic types of material if unknown.

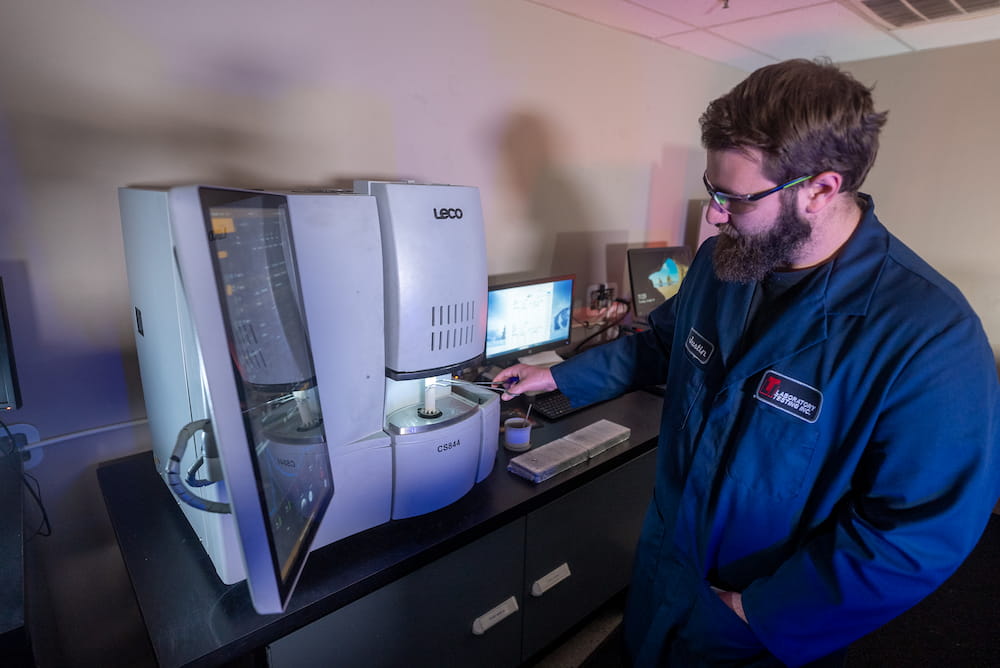

Combustion Analysis

LTI performs Carbon and Sulfur testing by high-temperature combustion analysis. The non-dispersive infrared cells used by our LECO Corporation analyzers can determine a wide range of Carbon and Sulfur content in steels, ores, alloys, and finished metals.

Inert Gas Fusion Analysis

Oxygen, Nitrogen, and Hydrogen are performed by inert gas fusion on our LECO Corporation analyzers. These gasses are found in materials as a result of melting processes and subsequent hot and cold working methods. Managing gas contents at low levels minimizes their adverse effects on the materials’ mechanical properties. Our instruments can deliver wide range measurements of Oxygen, Nitrogen, and Hydrogen for ferrous, non-ferrous, and refractory alloys.

Additional Analytical Chemistry Testing

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.