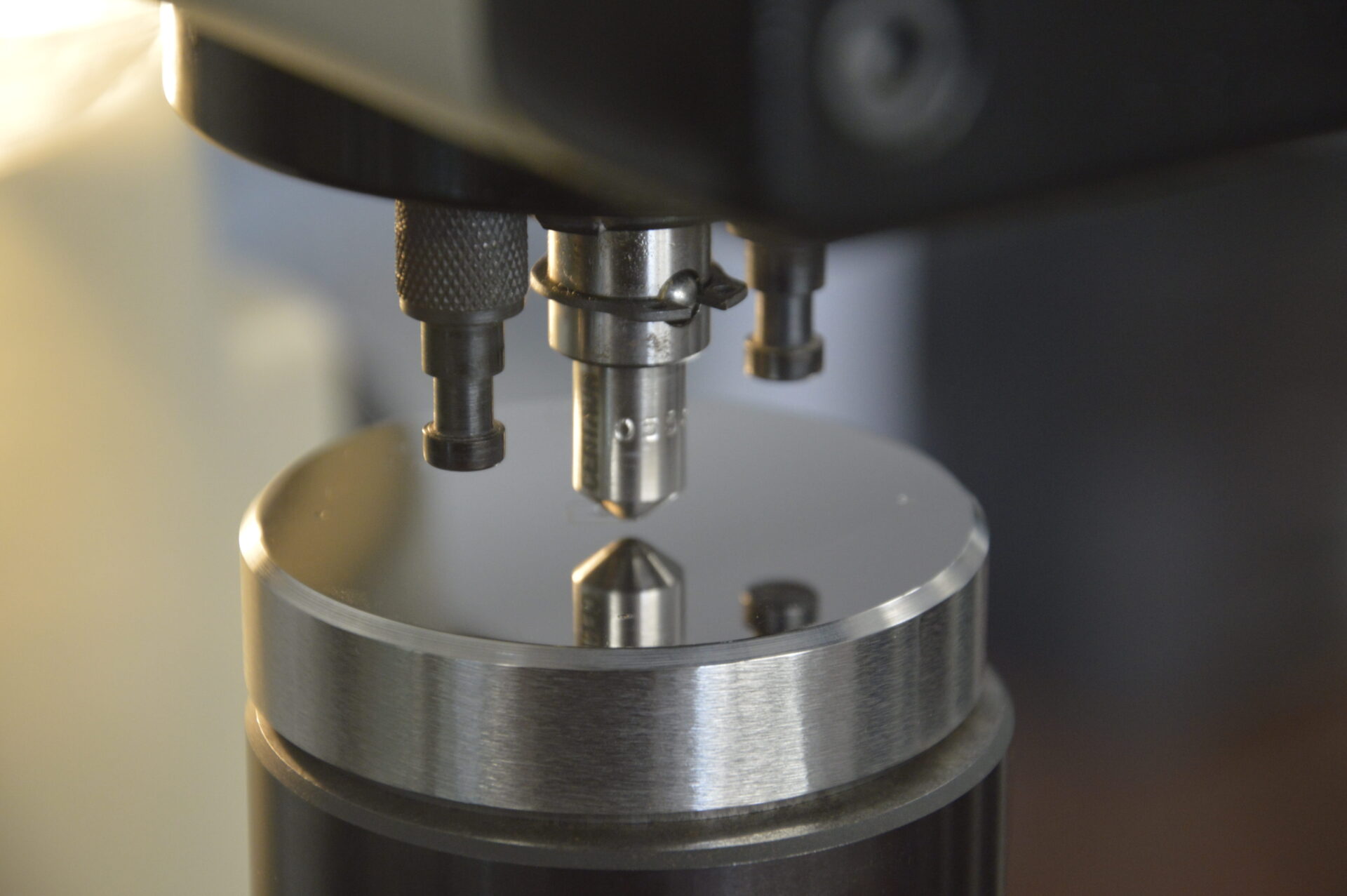

Hardness testing uses various methods to determine a material’s susceptibility to localized plastic (non-reversible) deformation. While most hardness testing relies on indentation mechanisms, determining hardness from surface abrasion is also possible. Hardness may reflect complex microstructure interactions, but testing methods are relatively straightforward compared to the physics at play. Regular hardness tester calibration must be a part of any lab where material selection and manufacturing processes require reliable, accurate measurements.

LTI Metrology Capabilities

The Hardness Tester Calibration Process

Full-Service Calibration for Hardness Testers

LTI Makes Hardness Testing Easy

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.