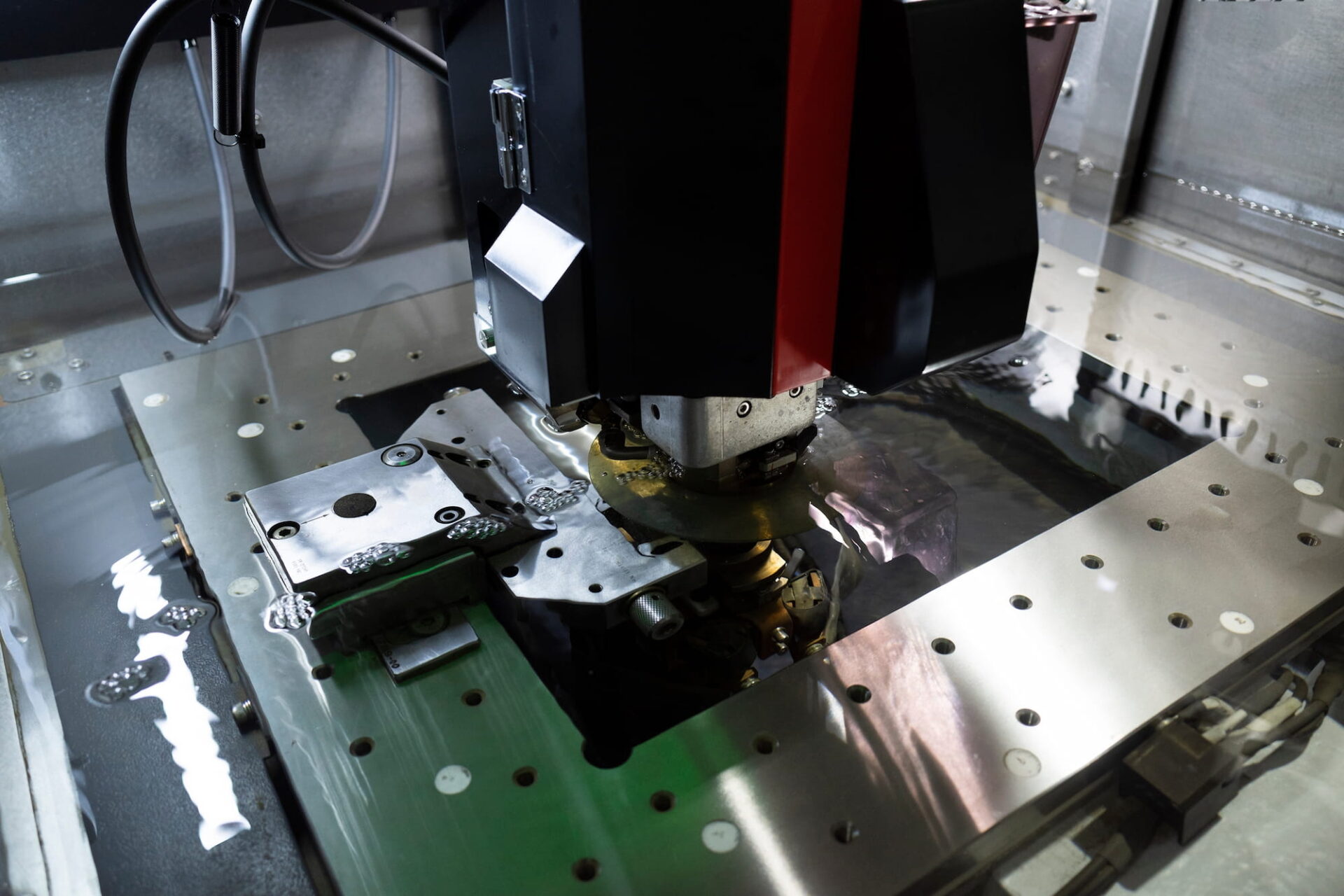

Laboratory Testing Inc. (LTI), near Philadelphia, performs hardness testing on metallic materials. The testing methods include a variety of micro-hardness and macro-hardness testing services. Metal hardness testing is performed to ASTM specifications as well as other standards and customer requirements for the type of material and application. Our machine shop can prepare all test specimens on-site for speedy turnaround.

What Is Metal Hardness Testing?

Metal hardness testing determines a metal’s strength by measuring its resistance to penetration. Hardness test results can be beneficial when selecting materials because the reported hardness value indicates how easily the metal can be machined and how well it will wear. Hardness testing of metal is routinely performed to assess the value of treatments and coatings.

How Does LTI Conduct Metal Hardness Testing?

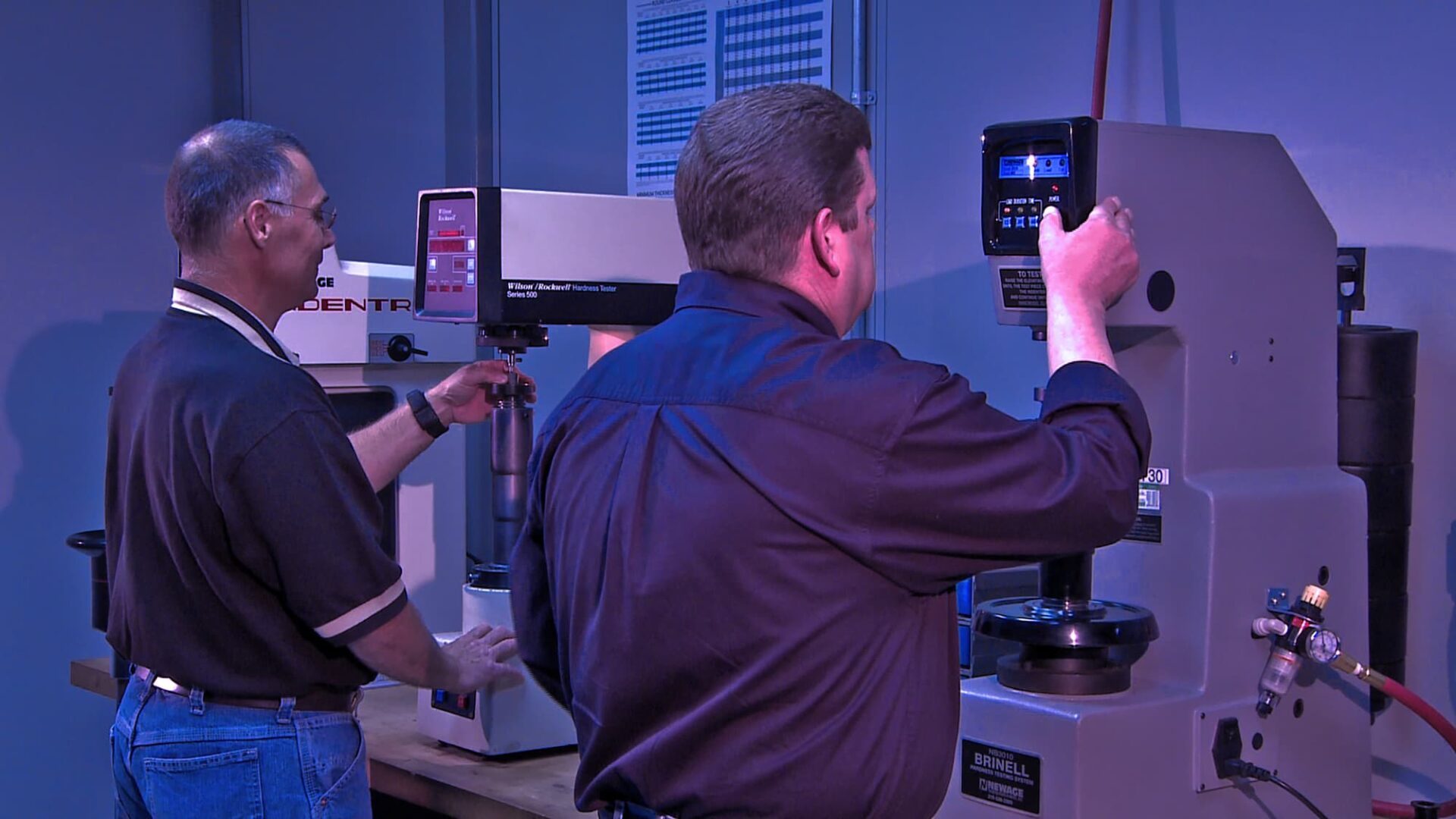

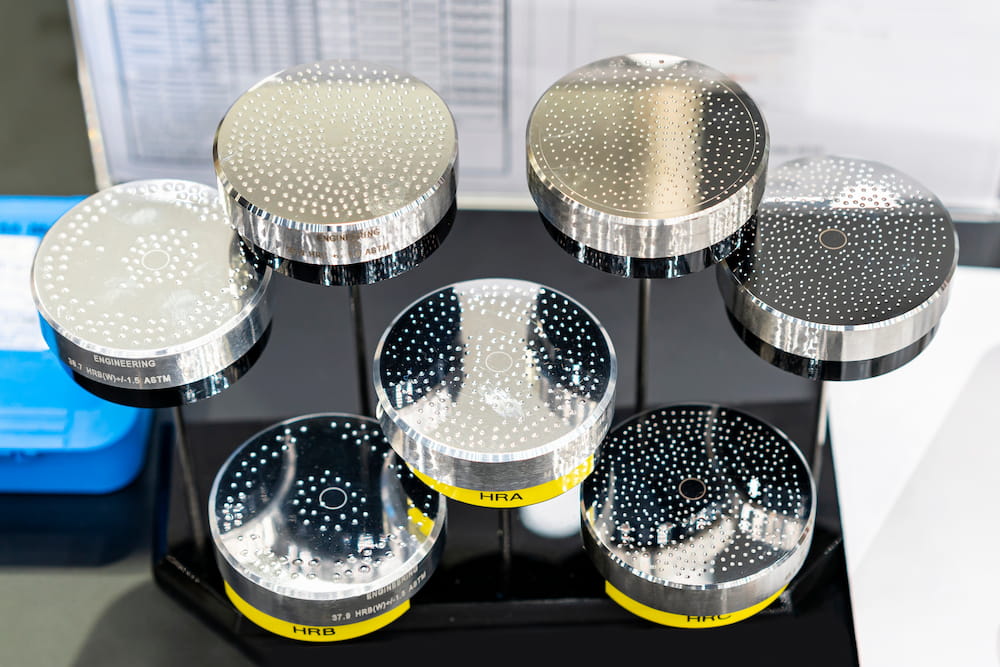

LTI’s metal hardness testing is performed using test machines equipped with an indenter that is forced into the test material over a certain amount of time. The shape of the indentor varies by type of hardness test and includes cone, ball, and pyramid shapes. Each test machine uses a different force or load application system and records an indentation hardness value in kilograms-force according to their hardness scales.

Metal Hardness Testing Capabilities at LTI

Standards

The LTI Advantage

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.