Testing for Fabricators and Manufacturers of Mission Critical Parts

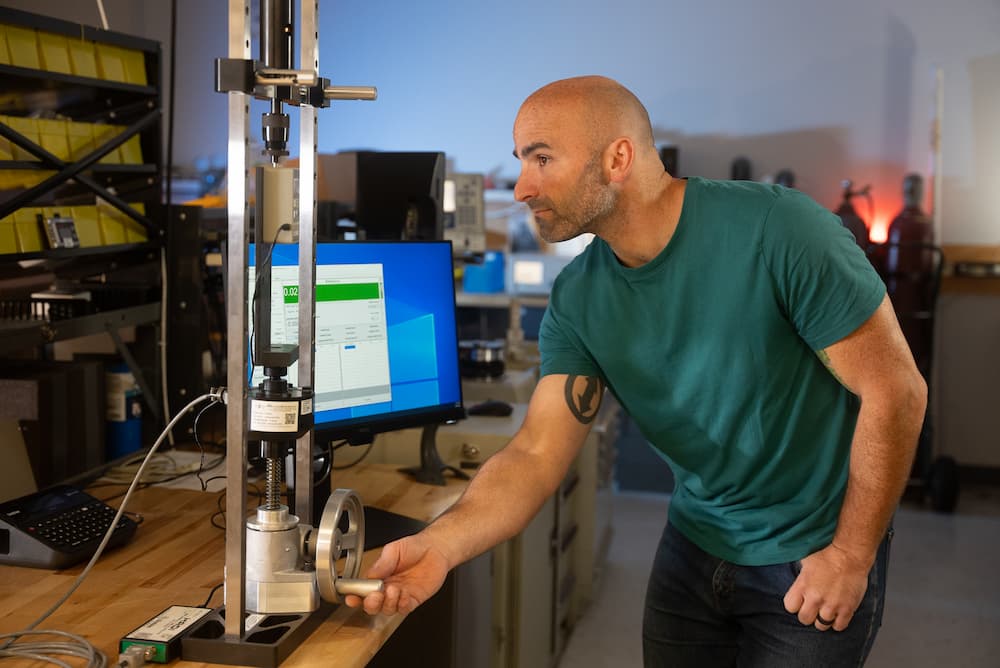

Laboratory Testing Inc., situated near the vibrant city of Philadelphia, PA, stands at the forefront of metal testing and analysis. Our esteemed and independent laboratory has been diligently offering top-notch material testing services to the manufacturing and fabrication industries since our inception in 1984. Backed by a dynamic team of engineers, chemists, and technicians, we are renowned for our unparalleled technical proficiency, lightning-fast turnarounds, and pinpoint-accurate test results.

LTI provides:

Quality Assurance:

LTI’s extensive quality program is in place to ensure materials meet required quality standards and specifications, reducing the risk of substandard parts entering the manufacturing process.

One-Stop Shop:

We offer a wide range of services, including chemical analysis, mechanical testing, metallurgical analysis, non-destructive testing and calibration, providing a single source for your diverse testing needs.

Expertise and Technical Knowledge:

Our team of experienced engineers, chemists, and technicians offer insights, recommendations, and solutions to optimize your materials and processes.

Timely Support:

In mission-critical situations, we are ready to meet your urgent needs with expedited services.

Metallurgical Analysis

- Microstructure

- Microhardness

(Knoop & Vickers) - Grain Size (ASTM E112)

- Inclusion Rating (ASTM E45)

- Plating Thickness

- Carbide Precipitation

- Ferrite by Point Count

(ASTM E562) - Intergranular Attack /

Oxidation - Alpha Case

- Intergranular Corrosion

(ASTM A262) - Sensitization

- Surface Contamination

- Nodularity / Nodule Count

- Eutectic Melting

- Macro-etch (ASTM E340)

- Grain Flow

- Surface Condition

- Surface Finish

- Case Depth

- Carburization / Decarburization

- Weld Qualification

Chemical Analysis

- Positive Material Identification (PMI)

- Spectroscopy (ICP-AES, ICP-MS, AES)

- Fourier Transform Infrared Spectroscopy (FTIR)

- Carbon / Sulfur / Nitrogen / Oxygen / Hydrogen Determination

- Wet Chemistry

Corrosion Testing

- ASTM A262 Practice A, B, C, D, E

- ASTM G28 Methods A & B

- ASTM G48 Methods A & B

- ASTM A923 Method C

- Salt Spray / Salt Fog

- Humidity Testing

- Passivation Testing

- Temperature Testing

Mechanical Testing

- Tensile Testing

- Charpy Impact Testing

- Drop Weight Test

- Hardness Testing

- Hydrogen Embrittlement

- Weld Testing

Fatigue and Fracture

- Fracture Toughness Testing

- Fatigue Crack Growth Testing

- Low-cycle and High-cycle Fatigue Testing

Nondestructive Testing

- Ultrasonic Testing

- Hydrostatic Testing

- Magnetic Particle Inspection

- Liquid Penetrant Inspection

- X-ray Inspection (Radiography)

Calibration and Additional Services

LTI’s Services Stand the Test of Time

Get in Touch

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.