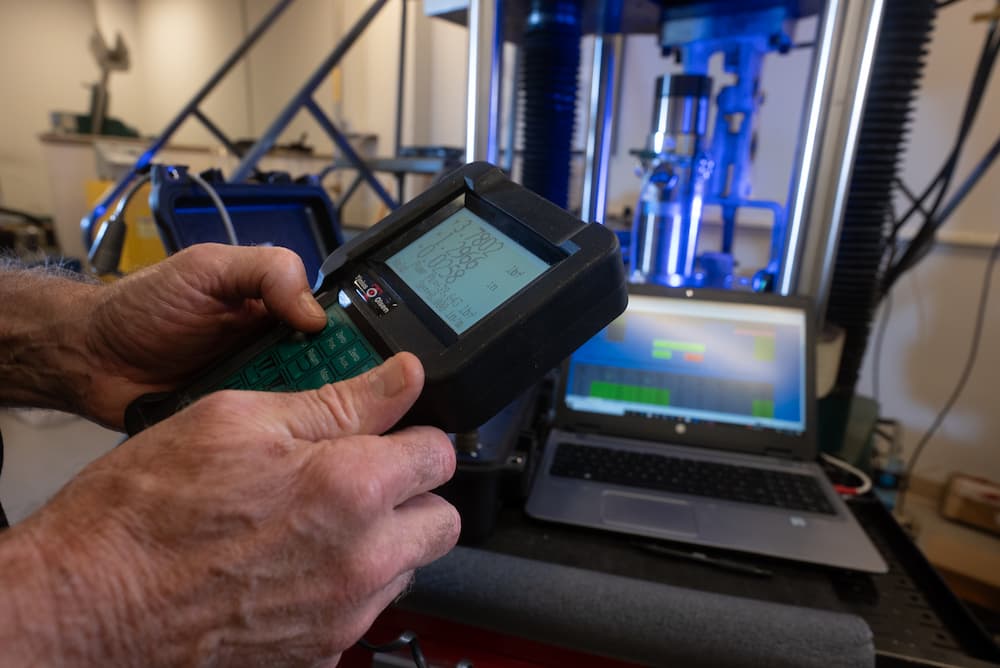

Manufacturers demand precision and accuracy from their calibration equipment to properly turn theoretical design data into real-world parameters. Without reliable instruments, the best-planned designs can fail in production as defects pile up and threaten profitability. Instrument calibration services – part of the material testing services offered at LTI – give our customers full confidence in their process control.

Instrument Calibration Services Keep Measurements True

Services

LTI Calibration Service Highlights

Calibration Is Instrumental to Manufacturing Success

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.