LTI provides cohesive testing solutions for our customers. By bundling a comprehensive package of testing services in a single source testing laboratory, we can significantly reduce your turnaround times when project schedules are balanced. As a one-stop material testing facility, we comprehensively analyze various materials while meeting your deadlines and quality requirements.

A Full-Service Materials Testing Laboratory

Chemical Analysis

- Spectroscopy (ICP-AES, ICP-MS, AES)

- Scanning Electron Microscopy / Energy Dispersive X-ray Spectrometry (SEM/EDS)

- Positive Material Identification (PMI)

- Fourier Transform Infrared Spectroscopy (FTIR)

- Wet Chemistry

Fatigue and Fracture Mechanics

- Fracture Toughness Testing

- Fatigue Crack Growth

- High-Cycle Fatigue

- Low-Cycle Fatigue

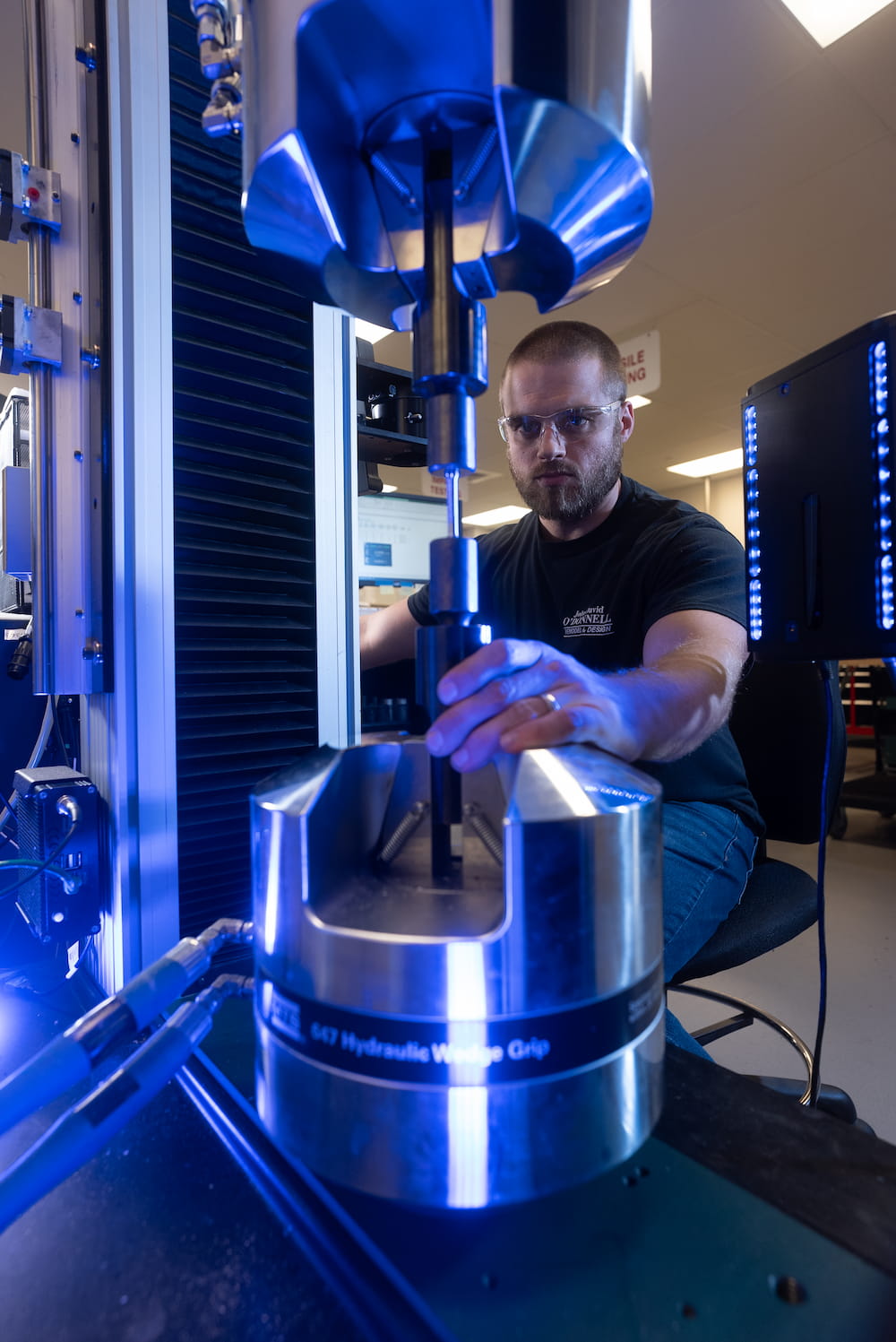

Mechanical / Destructive Testing

- Tensile Testing

- Elevated Temperature

- Charpy Impact Testing

- Hardness Testing

- Bend Testing

- Stress Rupture Testing

- Hydrogen Embrittlement

- Weld Testing

- Fastener Testing

Metallurgical Analysis

- Microstructure

- Carburization / Decarburization

- Grain Size (ASTM E112)

- Inclusion Rating (ASTM E45)

- Plating / Coating Thickness

- Intergranular Oxidation

- Alpha Case

- Intergranular Corrosion (ASTM A262)

- Hydrogen Embrittlement

- Macro-etch (ASTM E340)

- Grain Flow

- Microhardness (Knoop & Vickers)

- Surface Contamination

- Adhesion Testing

- Detrimental Intermetallic Phases in Duplex Austenitic / Ferritic Stainless Steels (ASTM A923, Method A)

Non-destructive Testing

- Ultrasonic Testing

- Magnetic Particle Inspection

- Liquid Penetrant Inspection

- X-ray Inspection (Radiography)

- Visual Examination

Additional Testing and Support

- Corrosion Testing – Determines the impact of environmental conditions on specimens

- Specimen Preparation – In-house machine shop

- Specimen Heat Treating – Our on-site furnaces treat materials; testing evaluates mechanical properties, microstructure, decarburization, and more after processing

Materials Tested

R&D or Production-Ready? LTI Covers Both

Meeting Quality Requirements

When Material Matters, Rely on LTI

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.