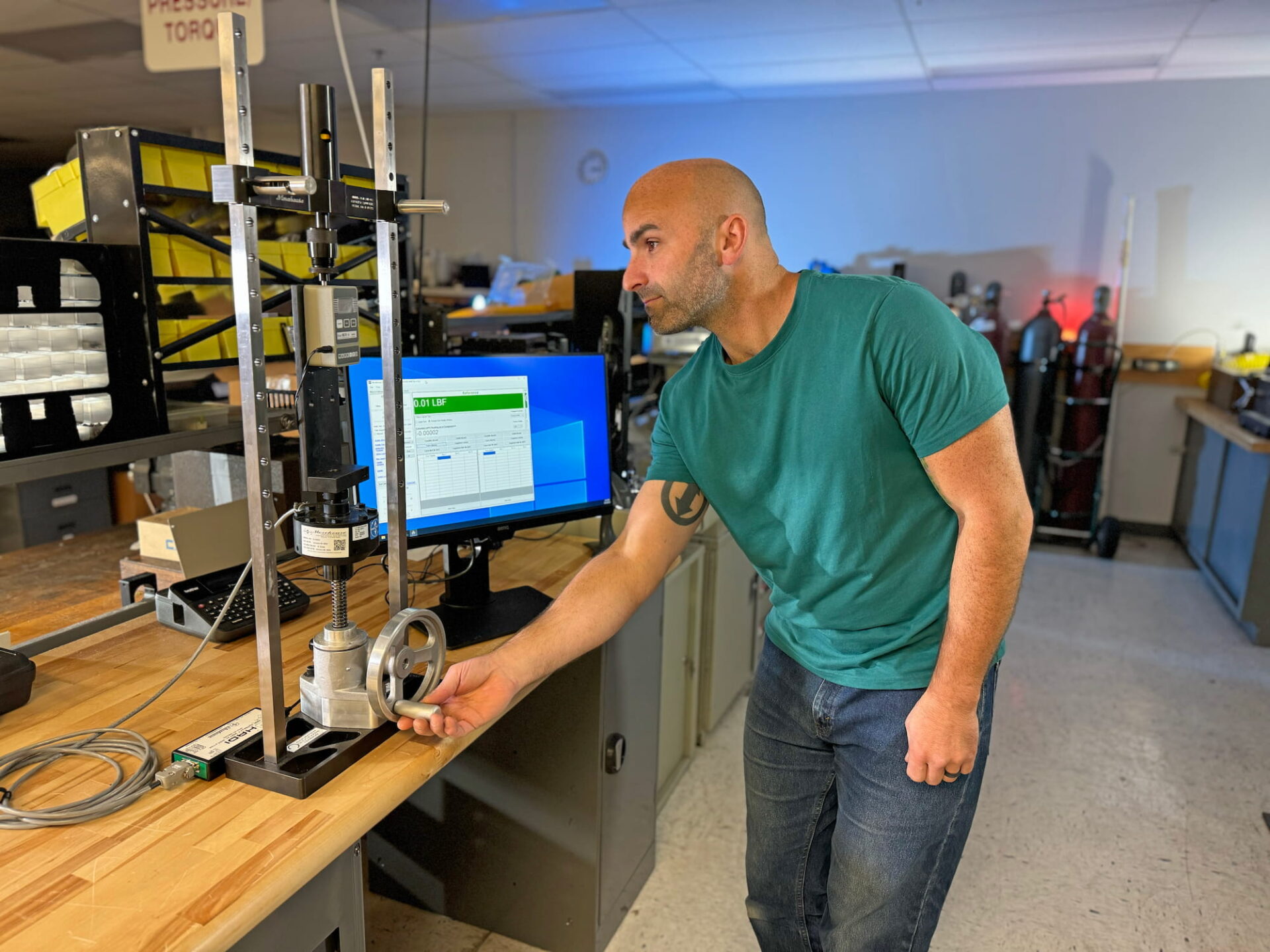

Keeping equipment calibrated – especially delicate devices that require specialty knowledge – is crucial for manufacturers to produce consistent results. LTI’s Metrology Lab in Pennsylvania comprises an experienced group of industry professionals and high-sensitivity calibration tools that can verify adherence to industry standards or provide repair and replacement services.

Our Metrology Lab Is Committed to Accuracy

LTI’s Metrology and Calibration Lab Highlights

Repair and New Instruments

Mechanical repairs and adjustments can occur in our calibration laboratory or the field. LTI Metrology can also provide replacement parts and new instruments from leading manufacturers

Dimensional Inspection

Ask us to verify the dimensions of machined parts, fasteners, and more. First article and third-party inspection services use CMM and Smartscope technology for a timely, reliable, and repeatable measurement.

Accreditations

Calibration services are A2LA accredited to ISO/IEC 17025. Calibration results are NIST-traceable and compliant with MIL-STD-45662A, ISO-10012-1, and ANSI/NCSL Z-540-1.

Calibration Domains

Learn MoreCustomer Portal

- Instant Visibility: Real-time calibration status insights.

- Order Tracking: Easily monitor calibration progress.

- Certificate History: Access past calibration records easily.

- Invoicing: Streamline billing and payments.

- Equipment Management: Efficient equipment inventory control.

- Notification Alerts: Timely maintenance reminders.

A Leading National Calibration Lab

Confirm Accuracy With LTI’s Calibration Services

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.