Despite its life-giving role in most organic systems, water can be a nuisance in inorganic systems as a catalyst for many failure modes. High-temperature manufacturing that does not remove water can undermine quality and outcomes. At Lab Testing Inc., our computerized analysis systems can rapidly perform moisture content analysis of a sample with multiple furnace operations and settings.

Why Use Moisture Content Analysis?

Moisture analysis is a test frequently ordered by businesses that rely on precision welding or purchase materials that contain moisture. Flux-coated electrodes can absorb moisture if not properly stored in a humid environment. Before welding, moisture determination can detect the presence of moisture, which can lead to porosity. The contamination of weld metal by trapped hydrogen as moisture breaks down during heating leaves voids in the weld bead; ultimately, it can lead to rejection depending on the welding job. In other situations, residual moisture can increase costs by misrepresenting the total material weight of a purchase.

Testing Operations

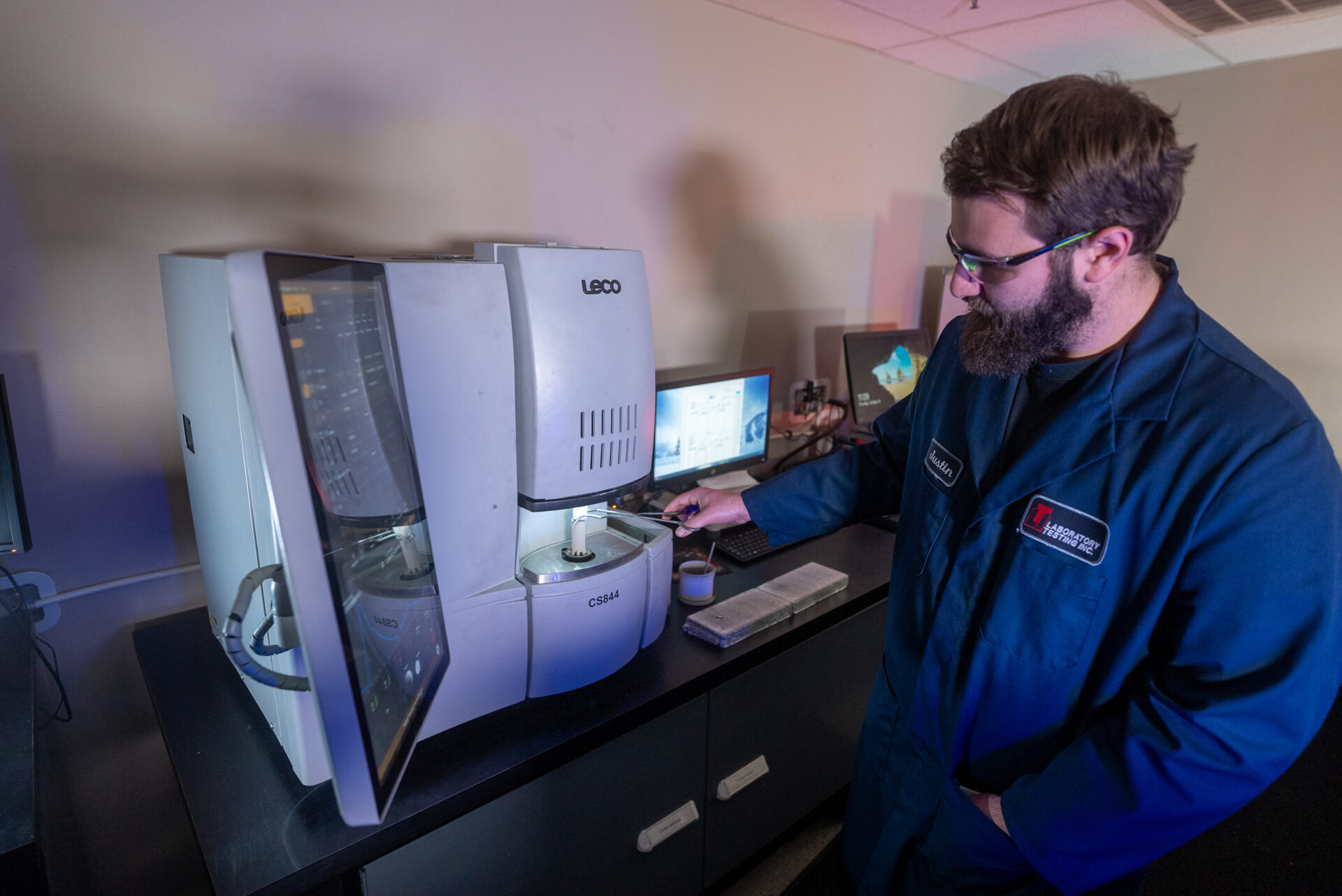

Our fully-computerized analyzer features a state-of-the-art furnace control system for temperature ramping from 25° to 1100°C. The analyzer uses radio frequency to heat the sample to the specified temperature to separate the moisture from the rest of the sample. A minimum of 20 grams of sample is necessary for analysis to quantify the moisture compared to a reference material. Reporting indicates moisture as a percentage of the total weight.

Moisture can be determined in three different ways:

- Gravimetric Determination – for determining moisture content at temperatures lower than 200° A sample is heated in a furnace for a period of time. The weight is taken before and after to determine moisture of the sample

- Absorbance Method – Oxygen is passed over a heated sample in a combustion tube. The oxygen carries the moisture from the sample to an absorption tube, which is weighed to determine moisture content

- IR Detection Method –Oxygen is passed over a heated sample. The moisturized gas is exposed to infrared radiation at specific wavelength and intensity to determine moisture content

Standards and Accreditations

- AWS A4.4 M – Moisture by Infrared Detection

- AWS A5.5 – Moisture by Absorbance Method

- NAVSEA T9074-AD-GIB-010 – Navy standard for weld materials for critical applications

Find Out How LTI’s Services Keeps Customers Content

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.