In destructive testing, materials succumb to failure modes that exceed their operational limits for safety and optimal service life. However, manufacturers may want to verify the contents of a material or process with a nondestructive test. Positive material identification, or PMI testing, uses physical properties to characterize materials without changing structure or performance. Since PMI testing does not consume any material under test, it is an excellent tool for preserving materials and labor costs.

Positive Material Identification

Fast, Accurate Verification and Identification

Positive Material Identification (PMI), known as PMI Testing, PMI Analysis, and PMI Inspection, provides fast compositional analysis of metals and alloys through a nondestructive test method. Laboratory Testing Inc. (LTI) delivers highly reliable qualitative and semi-quantitative PMI testing results in certified reports.

The PMI test analyzes chemical composition for material identification and verification purposes — confirming the material composition.

When PMI Testing Is an Option

PMI testing services are integral to quality control and safety compliance for businesses in many industries. Alloys specify corrosion resistance, temperature tolerance, or mechanical properties; a material error can result in component failure.

The PMI testing results verify that materials match what you ordered or that the material used matches specifications. Inspection can confirm that the material has a chemical composition consistent with certification documents or conforms to specifications. PMI analysis can identify the material grade.

Lab Qualifications

Highly skilled chemists and technicians and our strict quality system make LTI the right choice for PMI testing services.

- A2LA ISO/IEC 17025 accreditation

- Testing to industry standards and specifications

- PED approval by Lloyd’s Register

Test Methods/Specifications

- ASTM E572

- ASTM E1476

ICP Analysis is another method offered by LTI for providing in-depth information about the composition of a material, including trace analysis.

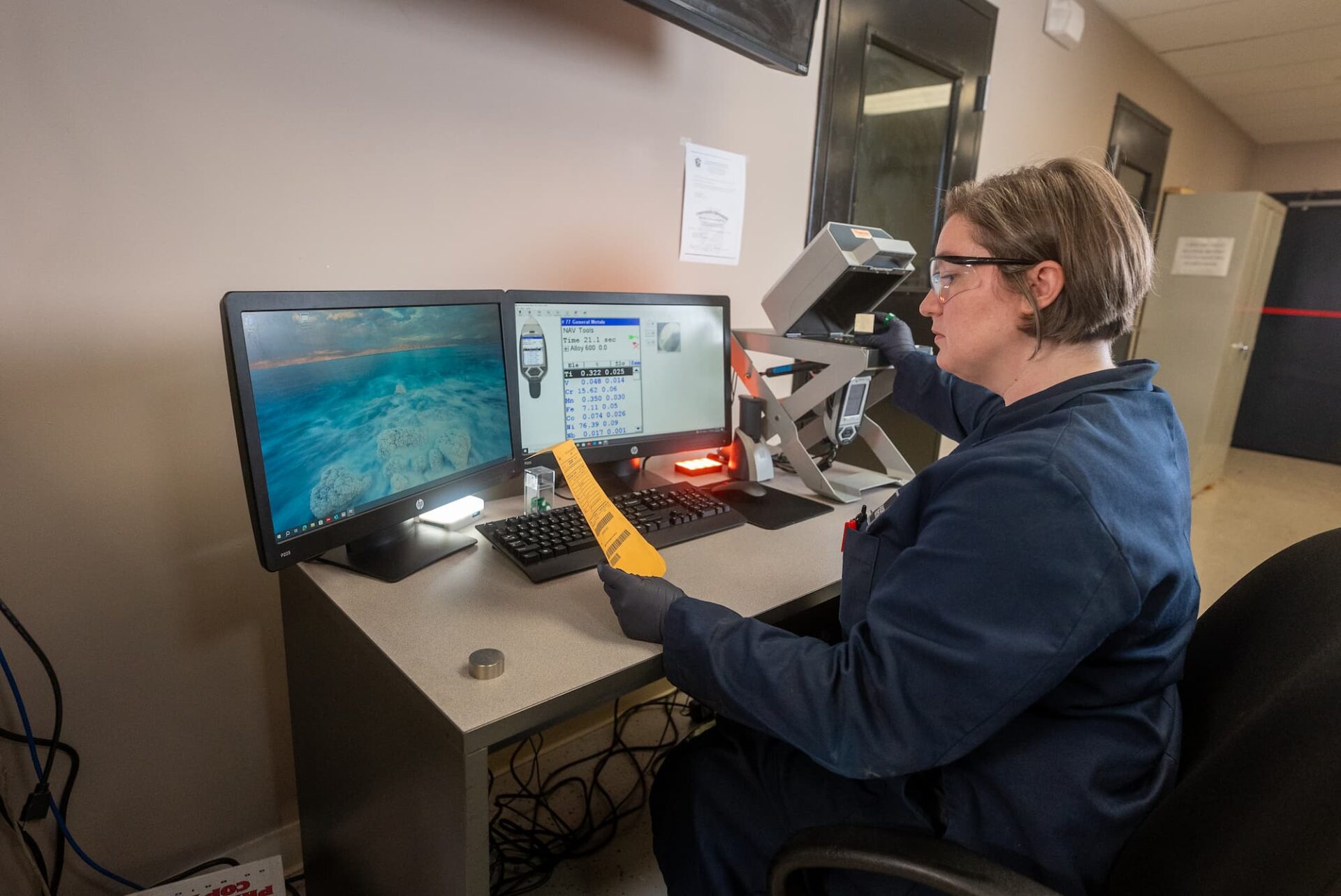

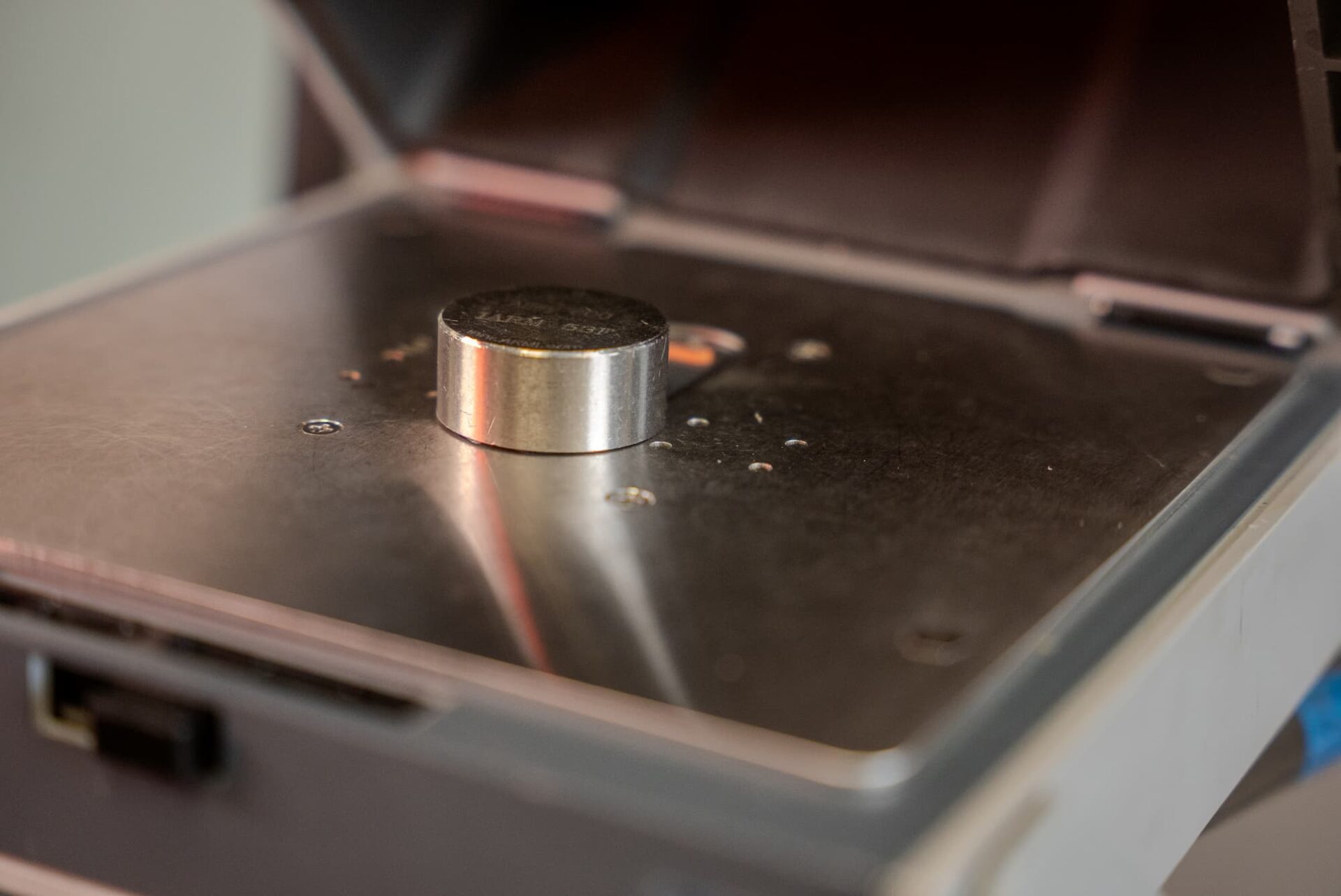

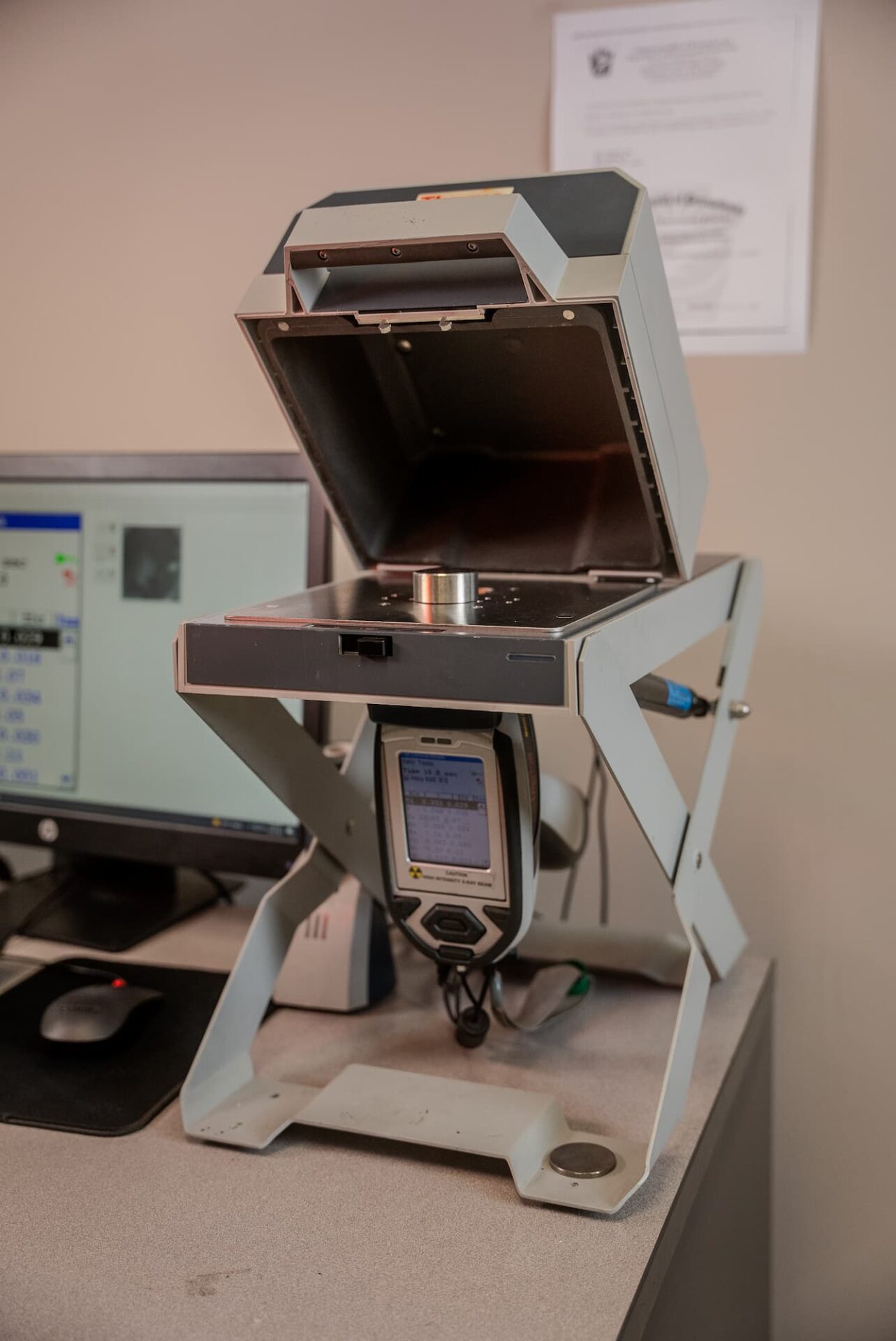

The Testing Process

The technicians at LTI use a state-of-the-art portable X-ray fluorescence spectrometer to perform PMI testing. This unit uses an X-ray tube instead of a radioactive source for faster analysis. The equipment directly analyzes solid metal samples for major elements and can be used for Restriction of Hazardous Substances (RoHS) screening of metallic and non-metallic samples.

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.