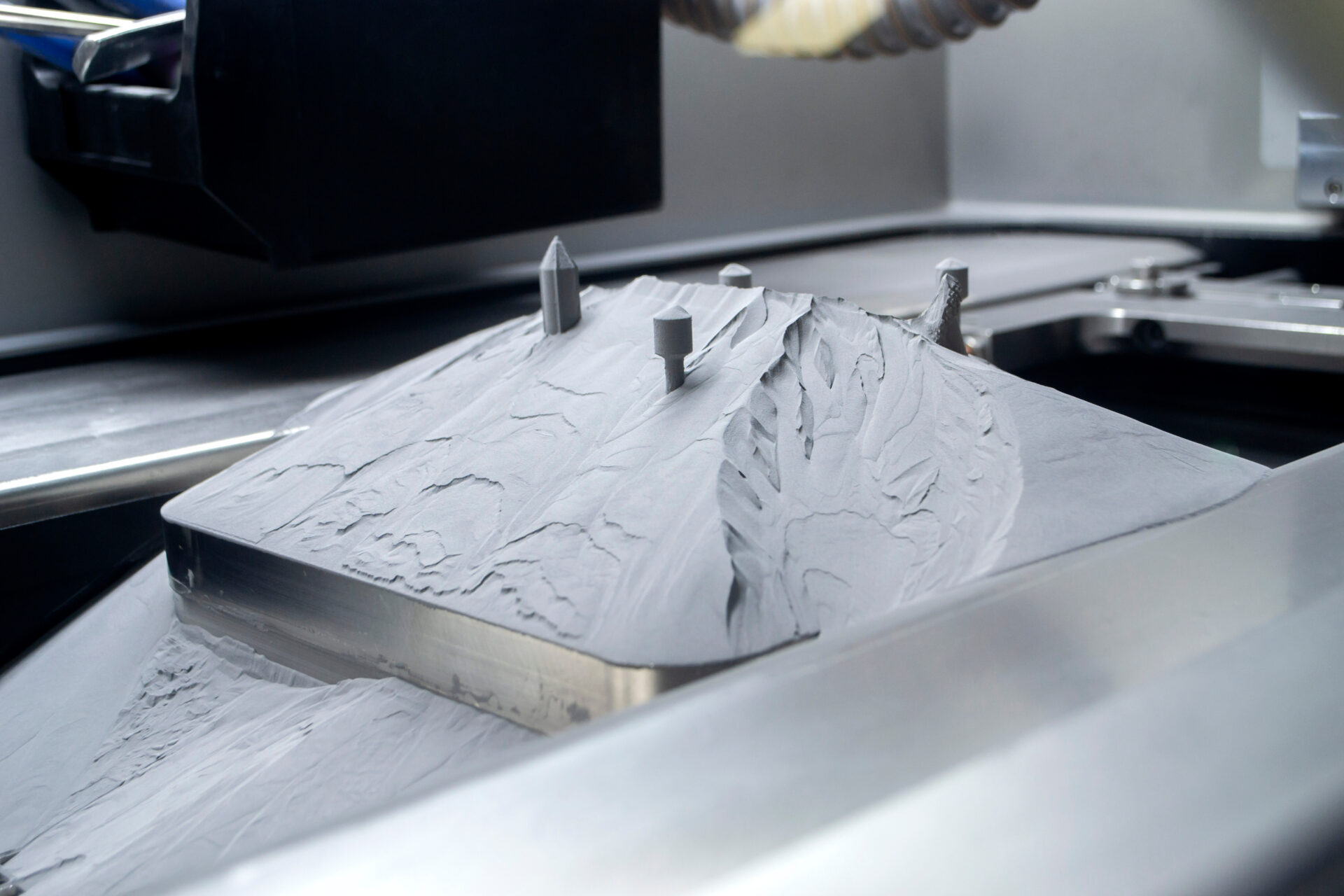

Additive manufacturing has enticing benefits over standard material removal methods to create the desired size or shape (now often called subtractive manufacturing). The additive method reduces process time and material consumption to fabricate the same product. With more precise forecasting of material quantity, manufacturers can reduce inventory and costs without sacrificing quality or throughput.

Additive Manufacturing Testing: From Powder to Product

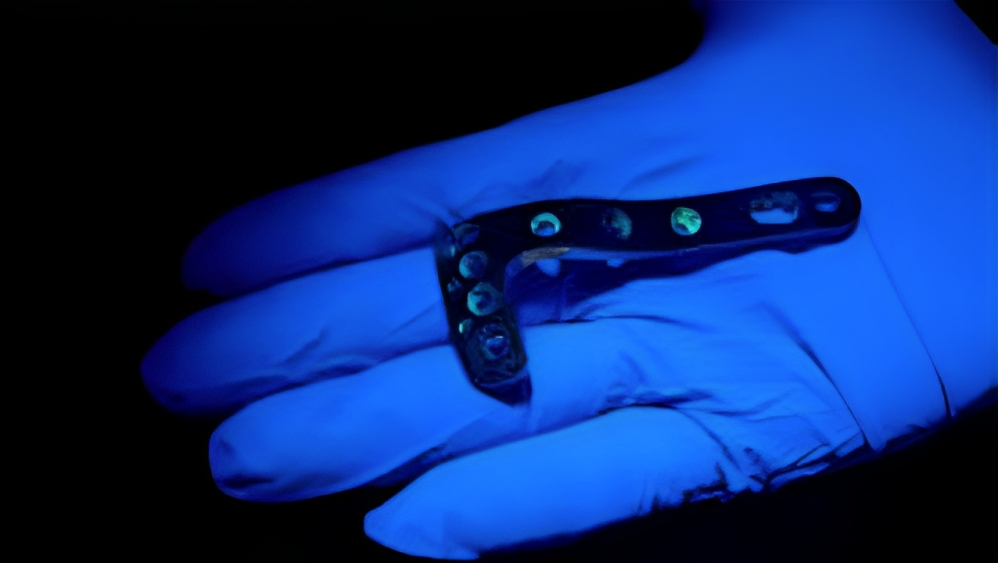

Material and Product Testing

Laboratory Testing Inc. offers metal additive testing services from feedstock to finished products. As your additive manufacturing testing lab, LTI offers a range of testing and analysis methods to help you improve the quality of your products. We can verify the quality of input materials, validate printing processes and assess the performance characteristics of the resulting products.

Specimen Machining

The Machine Shop at LTI can prepare all specimens and samples for destructive testing. Operating two work shifts, LTI provides reliable, fast turnaround. We excel at preparing high-quality, specialized specimens and have technical experts available for consultation.

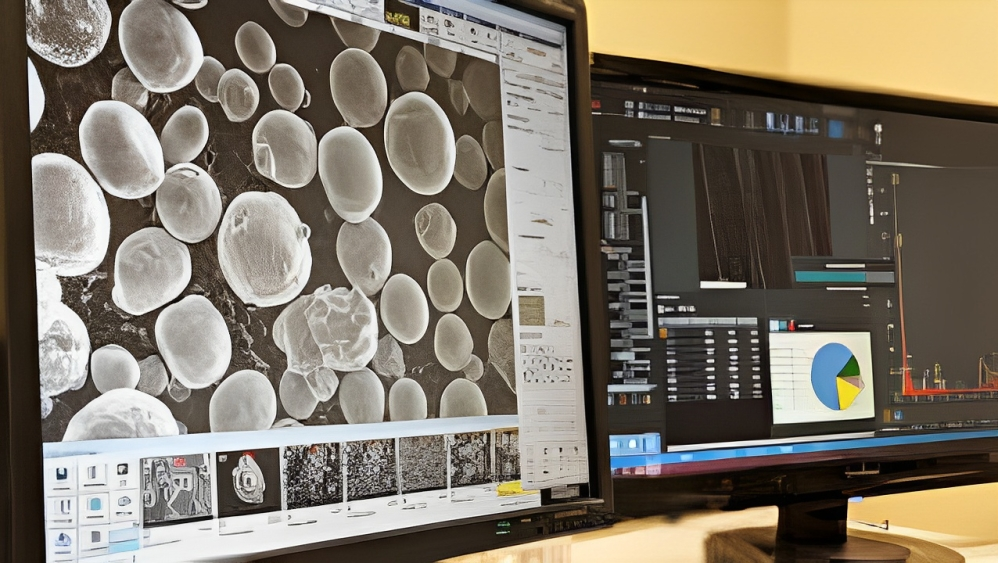

Metal Powder Characterization

LTI’s highly qualified and trusted engineers, chemists, and technicians can solve complex testing needs for your tight deadlines. Our metal powder characterization and 3D-printed metal testing services help manufacturers make essential decisions during product design, development, and production.

Our Services

Chemistry

- ICP-AES/OES – Bulk Elements

- ICP-Mass Spec – Trace Elements

- Interstitial Elements – C, S, O, N, H

- EDX Elemental Mapping

- ”Spark” AES

- Wet Chemistry

Metallography

- Grain Size

- Microstructure

- Density

- Macrostructure / Grain Flow

- Surface Contamination

- Alpha Case Analysis

- Microhardness

- SEM / EDX Analysis

Nondestructive

- Liquid Penetrant

- Magnetic Particle

- 2D Computed Radiography

- Ultrasonic Testing

- Visual Inspection

Fatigue & Fracture Mechanics

- High & Low Cycle Fatigue

- Fatigue Crack Growth

- Fracture Toughness

Mechanical Testing

- Tensile

- Compression

- Stress Rupture

- Creep

- Hardness

- Bearing and Shear

- Bend

- Charpy Impact

Specimen Machining

- Abrasive Waterjet & Wire EDM

- CNC multi-axis turning, milling & grinding

- Low Stress Grinding

- Specimen Polishing

See How LTI Adds Up

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.