With the abilities and increasing applications for additive manufacturing growing continuously, the value of powder metallurgy is ever-increasing. A shift from subtractive manufacturing methods that require greater material consumables and energy inputs will also, in the long term, offset concerns of immediate cost in the switch to additive manufacturing equipment and processes. Concerns about the quality and reliability of products will certainly ease as processes mature to the point of greater adoption.

Here at LTI, however, we believe the future is now: whether you’re a manufacturer introducing new processes or have extensive experience with press-and-sinter powder manufacturing, we offer complete metal powder testing using cutting-edge analysis and unrivaled industry expertise.

Metal Powder Testing and Analysis

Chemical Composition

| Test analysis | Methodology / Equipment | Restrictions |

|---|---|---|

| Bulk elements | ICP-AES/OES | Alloy dependent |

| Trace elements | ICP-MS (Mass spectrometry) | |

| Interstitial gases (oxygen, nitrogen, hydrogen) | Inert gas fusion – LECO | |

| Interstitial elements (carbon & sulfur) | Combustion – LECO | |

| Element mapping | SEM-EDX via SEM | Informational purposes only |

Particulate Properties

| Test analysis | Methodology / Equipment | Standards / Restrictions |

|---|---|---|

| Particle size distribution | Microtrac SYNC – light scattering/laser diffraction | ASTM B822 / ISO-13320-1 |

| Sieve analysis (20, 25, 32, 38, 45, 53, 63, 75, 106, 125, 150, 180, 250, 425, 600, 800 µm) | ASTM B214 / ISO-2591 | |

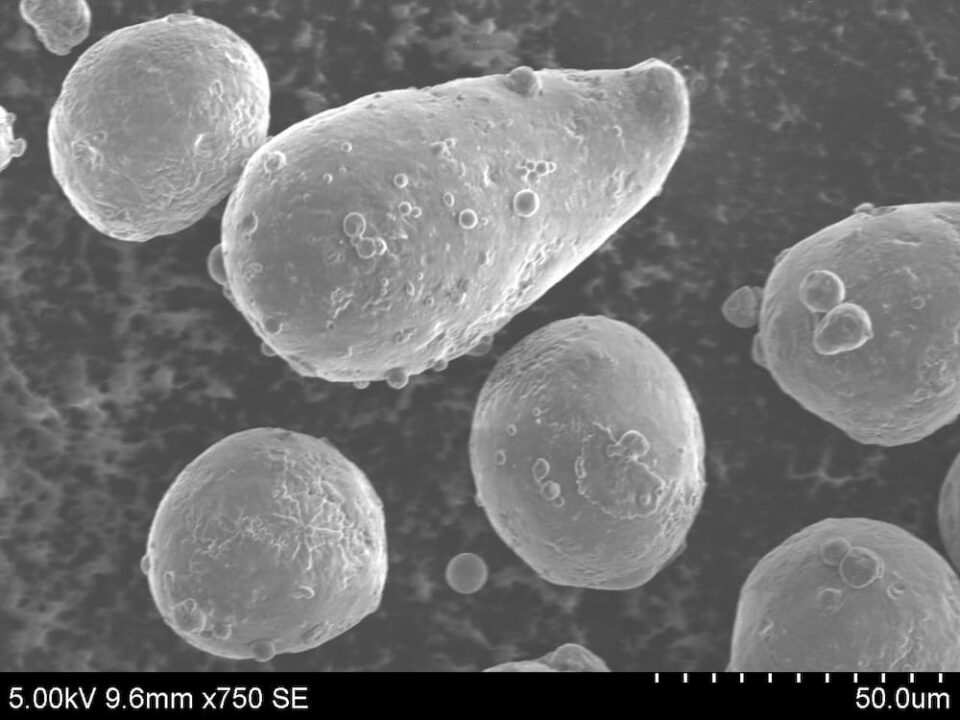

| Particle size and shape analysis – Morphology | Microtrac SYNC – dynamic image analysis | ISO 13322-2 |

| Particle shape analysis – Morphology | SEM (100X, 200X, 500X photos) | Informational purposes only |

| Specific surface area | Physical adsorption | ASTM B922 |

Flow Analysis

| Test analysis | Methodology / Equipment | Standards / Restrictions |

|---|---|---|

| Powder flowability (free-flowing) | Hall flowmeter | ASTM B213 / ISO 4490 |

| Powder flowability (not free-flowing) | Carney flowmeter | ASTM B964 |

| Dynamic flow rates | Avalanche-Drum rheometer | Informational purposes only |

Density Analysis

| Test analysis | Methodology / Equipment | Standards |

|---|---|---|

| Apparent powder density (free-flowing) | Hall funnel | ASTM B212 / ISO 3923-1 |

| Scott volumeter | ASTM B329 / ISO 3923-2 | |

| Apparent powder density (not free-flowing) | Carney funnel | ASTM B417 / ISO 3923-1 |

| Tap density | Balance & graduated cylinder | ASTM B527 / ISO 3953 |

| Skeletal density | Gas pycnometry | ASTM B923 / ISO 12154 |

Moisture Content

| Test analysis | Methodology / Equipment | Standards / Restrictions |

|---|---|---|

| Moisture analysis | Absorbent method | Informational purposes only |

| Karl Fischer titration | ASTM E203 |

Contamination or Cleanliness

| Test analysis | Methodology / Equipment | Restrictions |

|---|---|---|

| Cross-contamination | EDS/EDX via SEM | Informational purposes only |

| Cleanliness | Microscopy 20x | Informational purposes only |

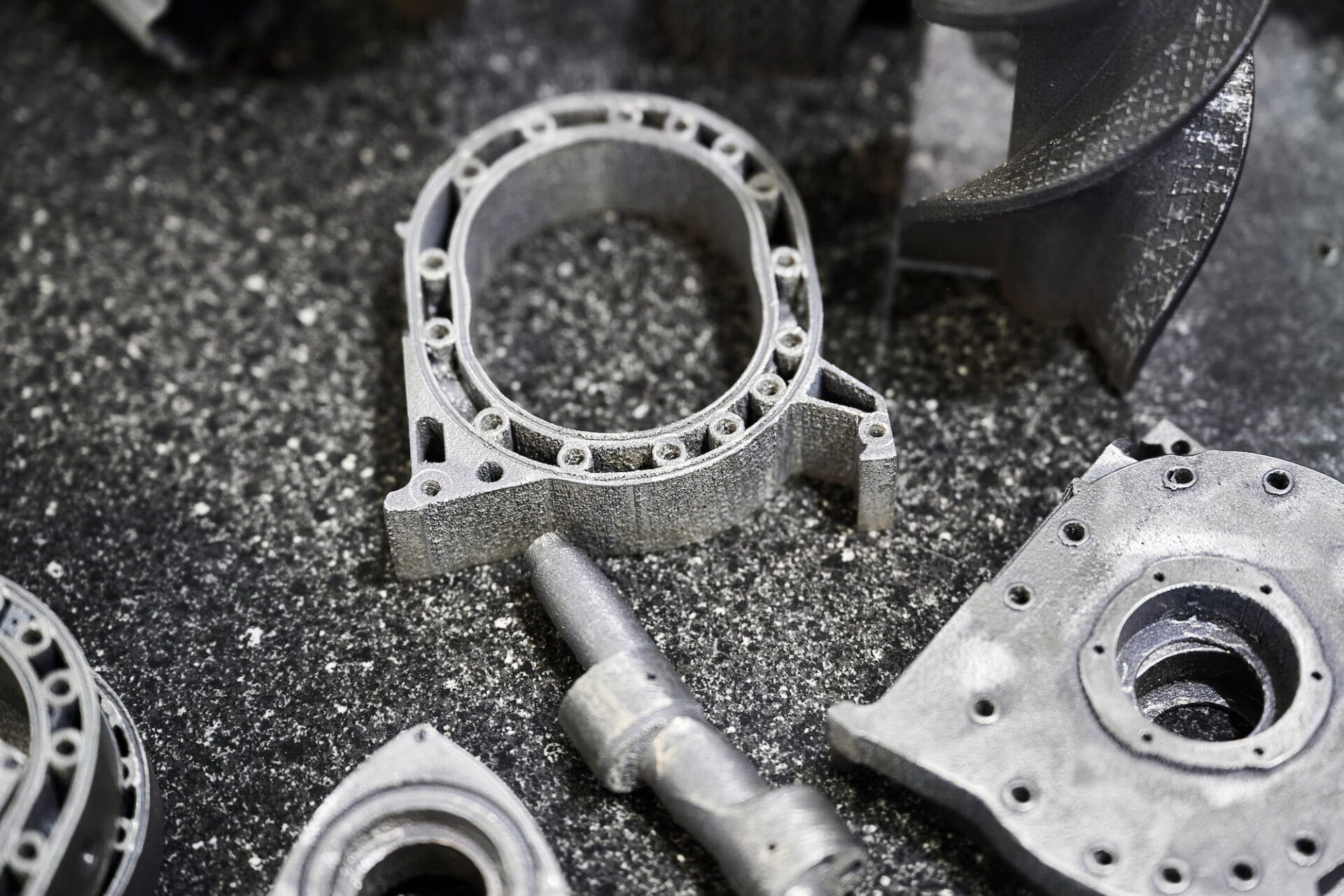

Support for Additive Manufacturing

Comprehensive Powder Characterization

LTI provides comprehensive metal powder analysis to characterize the raw materials used in additive manufacturing. LTI analyzes your powdered metals to confirm that the raw material has the correct chemistry, particle size distribution, and physical and mechanical properties. An early step in the additive manufacturing process is verifying that powders from a supplier meet expectations. Powder characterization evaluates the raw material for purity and uniformity between batches and determines if the powder is ready for additive manufacturing.

Powder Management Solutions

LTI helps manage your inventory by testing a variety of metal powders for appropriate feedstock selection, including virgin powder validation, blended powdered checks, recycled powders, and 100% lot traceability. As a material tester since 1984, LTI contributes to many of the committees shaping industry best practices for operations directly impacted or adjacent to powder characterization:

- ASTM F42

- ASNT

- AMS

- ITA Medical Technology

Utilizing Technology in Tandem for Comprehensive Analysis

Microtrac SYNC Laser Diffraction vs. SEM Image Analysis

LTI Capabilities

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.