Macroscopic examination of metals evaluates the quality and consistency of a test sample using only low or no magnification. It can be used to assess quality by evaluating a sample’s macrostructural features, which may include grain flow, porosity, and cracks.

LTI’s Macroscopic Examination Capabilities

Why This Method?

Macroscopic examination of specimens exposed to passivation, salt spray, case depth, and other testing are frequently performed. For example, a weld cross-section examination can reveal internal discontinuities, weld profile, extent of penetration, and more. The macrostructural properties of a weldment can be crucial in weld procedures or welder qualifications.

How Does LTI Conduct This Testing Method?

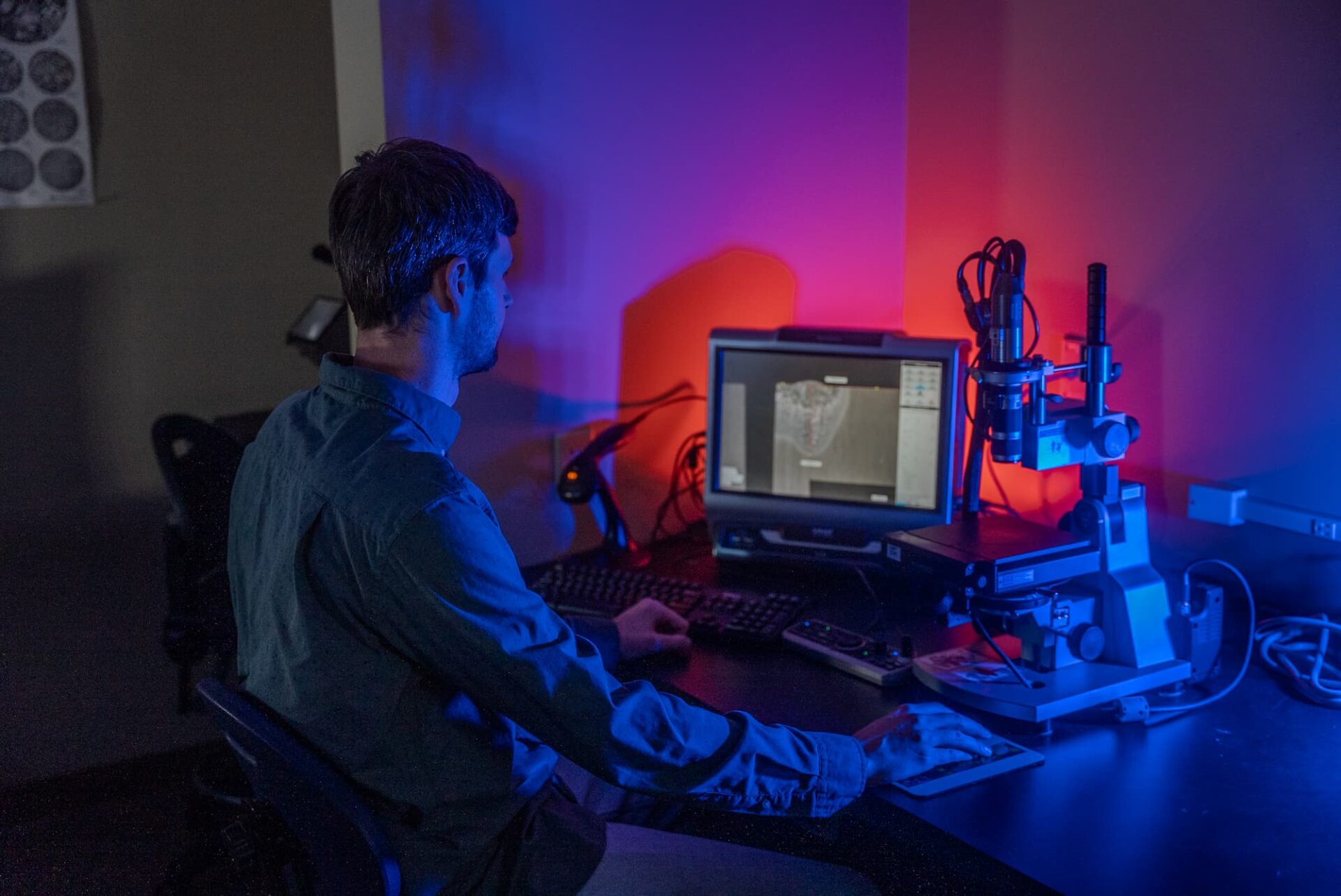

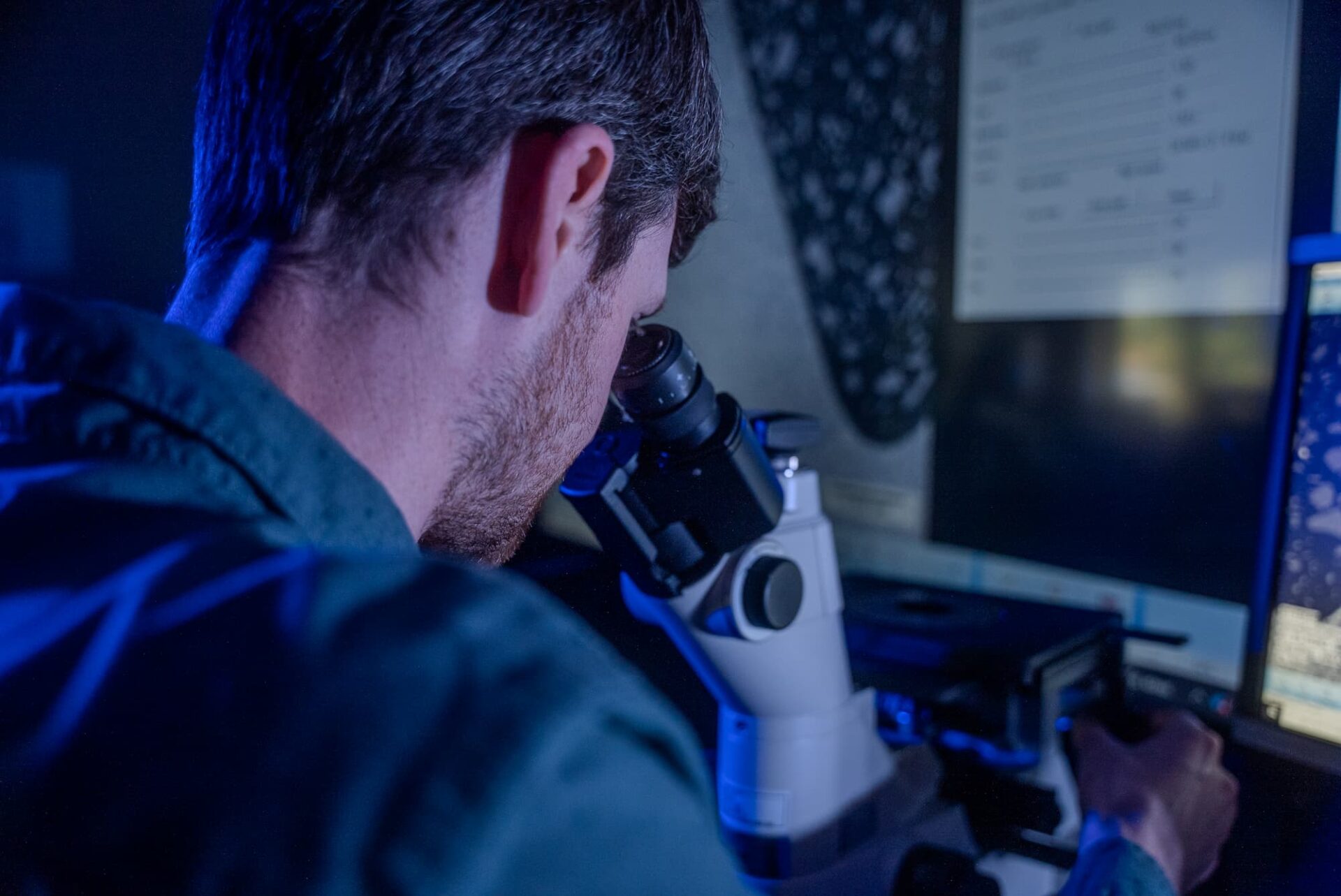

Before macroscopic examination of metals begins, LTI prepares the test sample to specification. Often etching is required after the sample has been cut, ground, and polished. The samples can be ingots, castings, plates, bars, sheets, or finished products. The macroscopic examination may be performed on the transverse or longitudinal cross-section of the test sample. The sample is viewed with the unaided eye or at low magnification, usually no greater than 10 times.

Specifications

- ASME Sect. IX

- ASTM E340

- ASTM E381

- MIL Specifications

The LTI Advantage

LTI’s cutting-edge facilities and expert metallurgists can handle all your material testing needs. During macroscopic examination of metals, LTI documents the findings with digital imaging to provide you with a visual record or a digital file that can be emailed.

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.