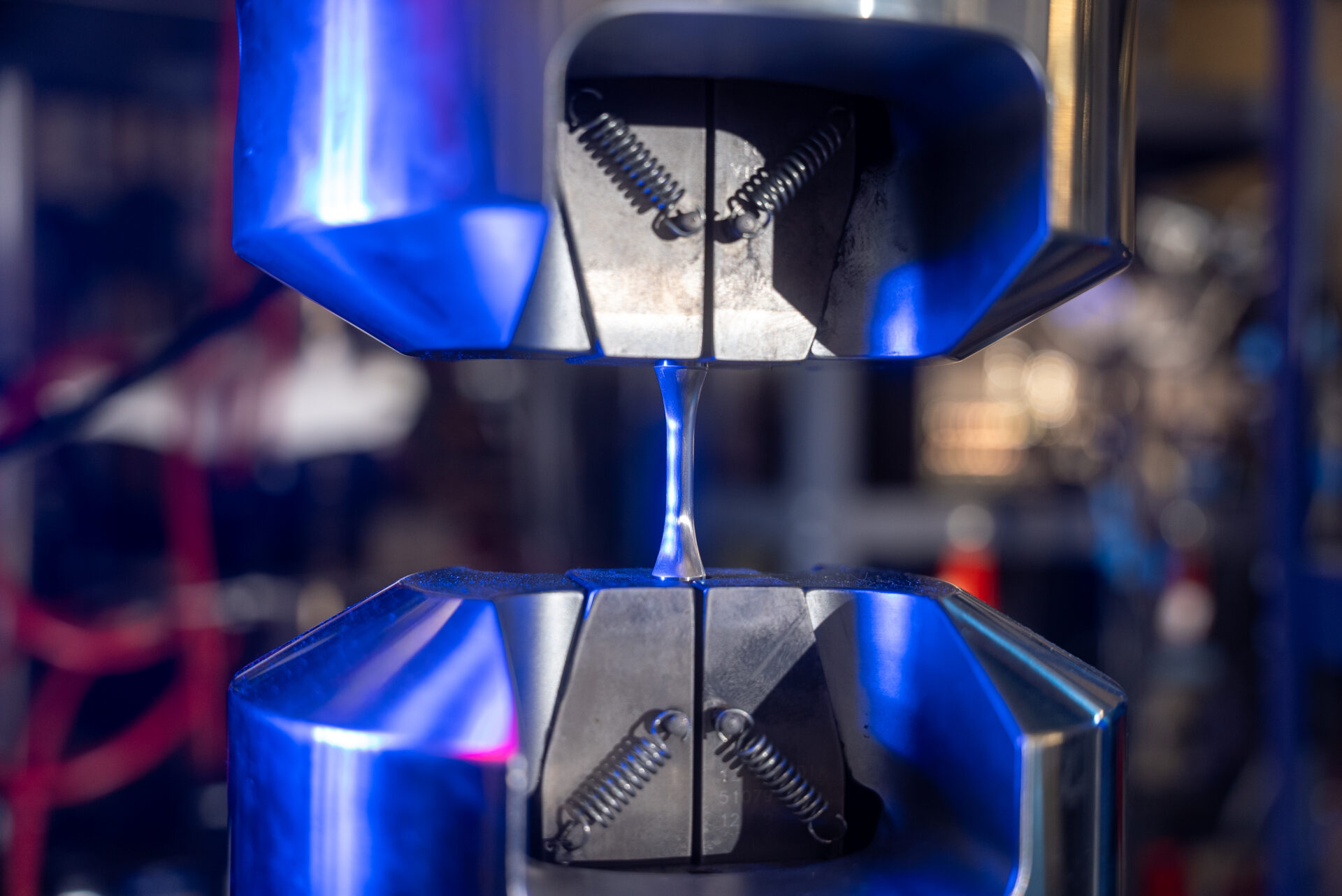

Material breakdown rarely happens all at once. Usually, it is more a matter of a gradual build-up of lifetime stressors that eventually overcome structural integrity. The best visual example of this is cracking: whether on a windshield or phone screen, most people have slowly seen a small crack eventually grow much larger.

Like most material wear processes, failure is inevitable once propagation begins, but the question is, “How long will it take?” At LTI, we can answer that question with fatigue crack growth testing.

These tests use various operating conditions and specimen types to study the rate at which cracks propagate in material, giving product developers a baseline for maintenance or repair-replace schedules.

The Basics of Fatigue Crack Growth Testing

Methodology |

Specimen Preparation |

Testing Scope |

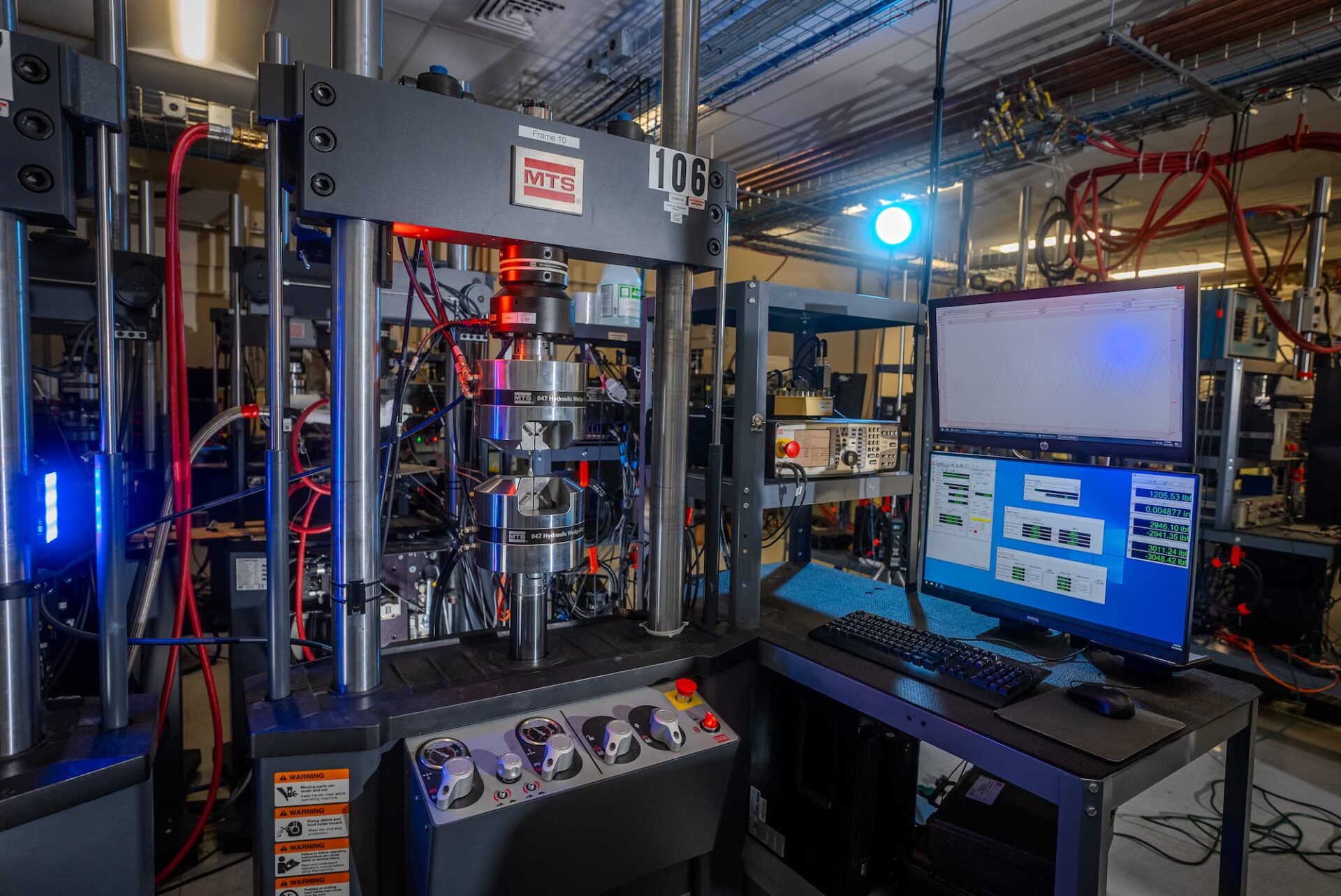

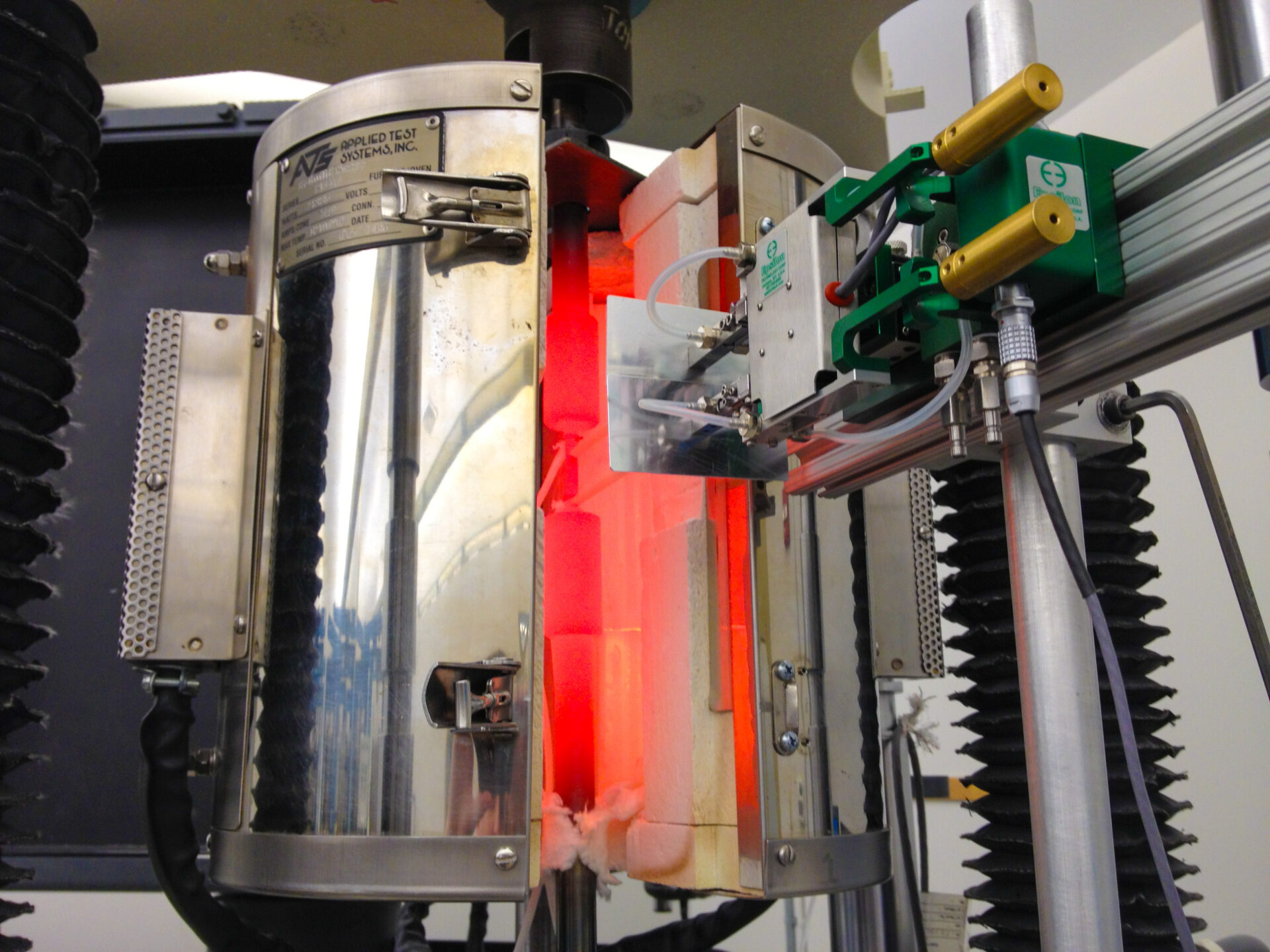

| Fatigue crack growth testing characterizes the rate at which a preexisting crack will grow under a time-varying crack tip driving force. Also known as crack propagation or da/dN testing, fatigue crack growth tests at LTI using compliance and DC potential drop-crack length measurement techniques. Analysis methods for materials use either K or load control. Advanced custom testing methodologies are also available to characterize threshold and complete Region I, Region II (the “Paris” regime), and Region III crack growth. | Test specimens are machinable in all standard geometries. Compact tension (C(T)) and middle tension (M(T)) specimen configurations in a range of sizes support fatigue crack growth analysis. The M(T) specimen is primarily for sheet materials, and the C(T) enables a range of different material forms, including sheet, plate, bar, and forgings. LTI can also prepare and test surface-flaw and SEN(T) specimens. Wire EDM creates starter notches, in this case. | Laboratory Testing Inc.’s highly experienced team provides fatigue crack growth testing at our greater Philadelphia lab. These tests conform to ASTM E647 and ASTM E2899. Variable-amplitude fatigue crack growth (spectrum testing) is also available, as well as dwell testing and custom customer waveforms. The Adjusted Compliance Ratio, compression pre-cracking, K-control, and constant Kmax testing are possible test options. |

Fatigue Crack Growth Test Results

During the fatigue crack growth test, a curve shows the crack growth rate change as the cyclic stress intensity factor (delta K) evolves; the test results also provide the data points and a da/dN-dK plot. Additionally, LTI also has the capability of providing customers with threshold and Paris Law values. LTI works with customers to offer adaptable testing for specific testing and engineering needs. The result of these tests is a curve displaying the crack growth rate as the cyclic stress intensity factor (ΔK) is varied. Test reports for fatigue crack growth testing include the following:

- Raw da/dN versus ΔK data

- A da/dN – ΔK plot

- Threshold or Paris Law values, as appropriate

Laboratory Testing Inc. offers a full scope of A2LA and PRI/Nadcap accredited mechanical testing services to evaluate material properties, including fracture toughness, stress rupture, elevated temperature tensile, hardness, Charpy impact, etc.

Capabilities

Group Your Material Testing at LTI

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.