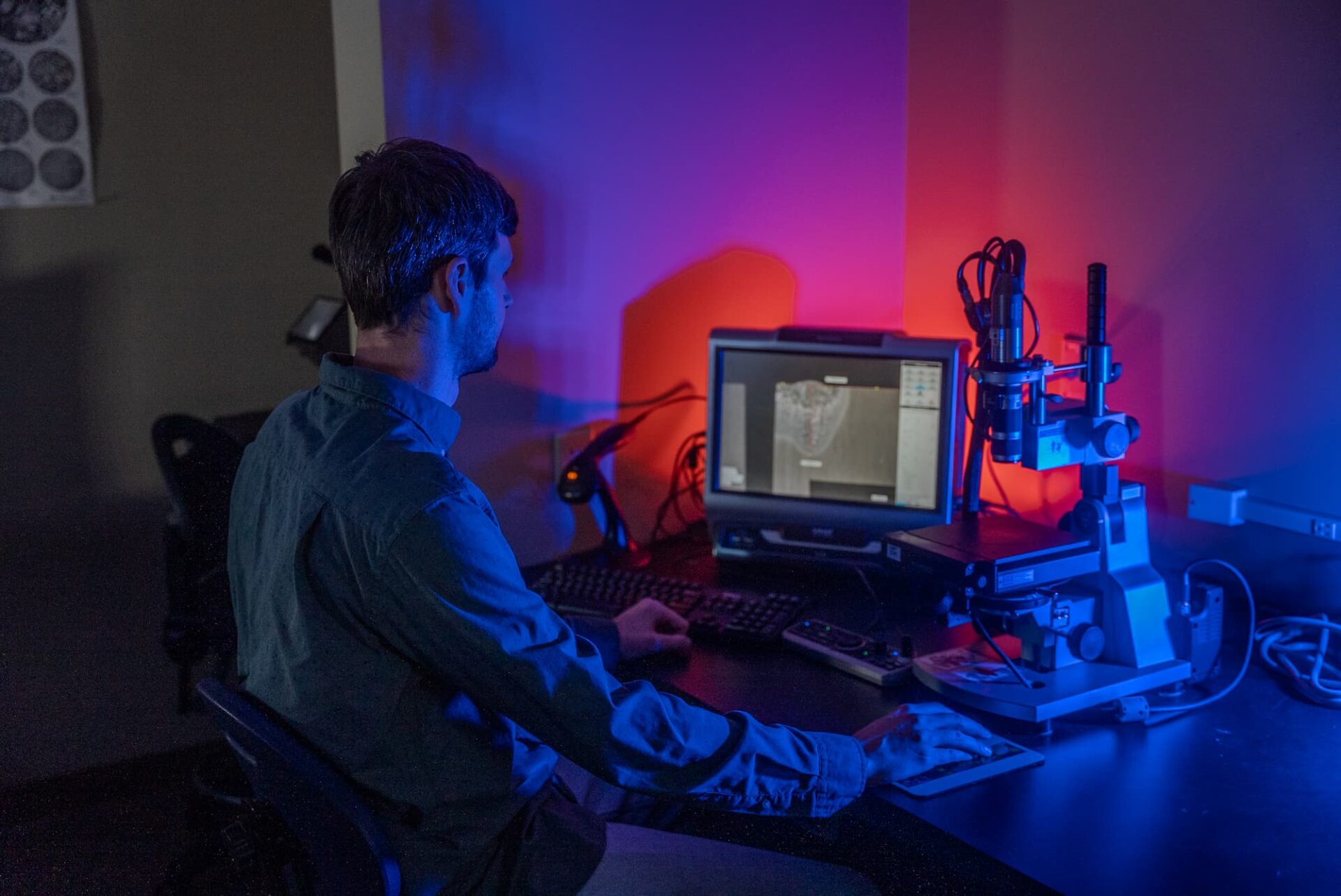

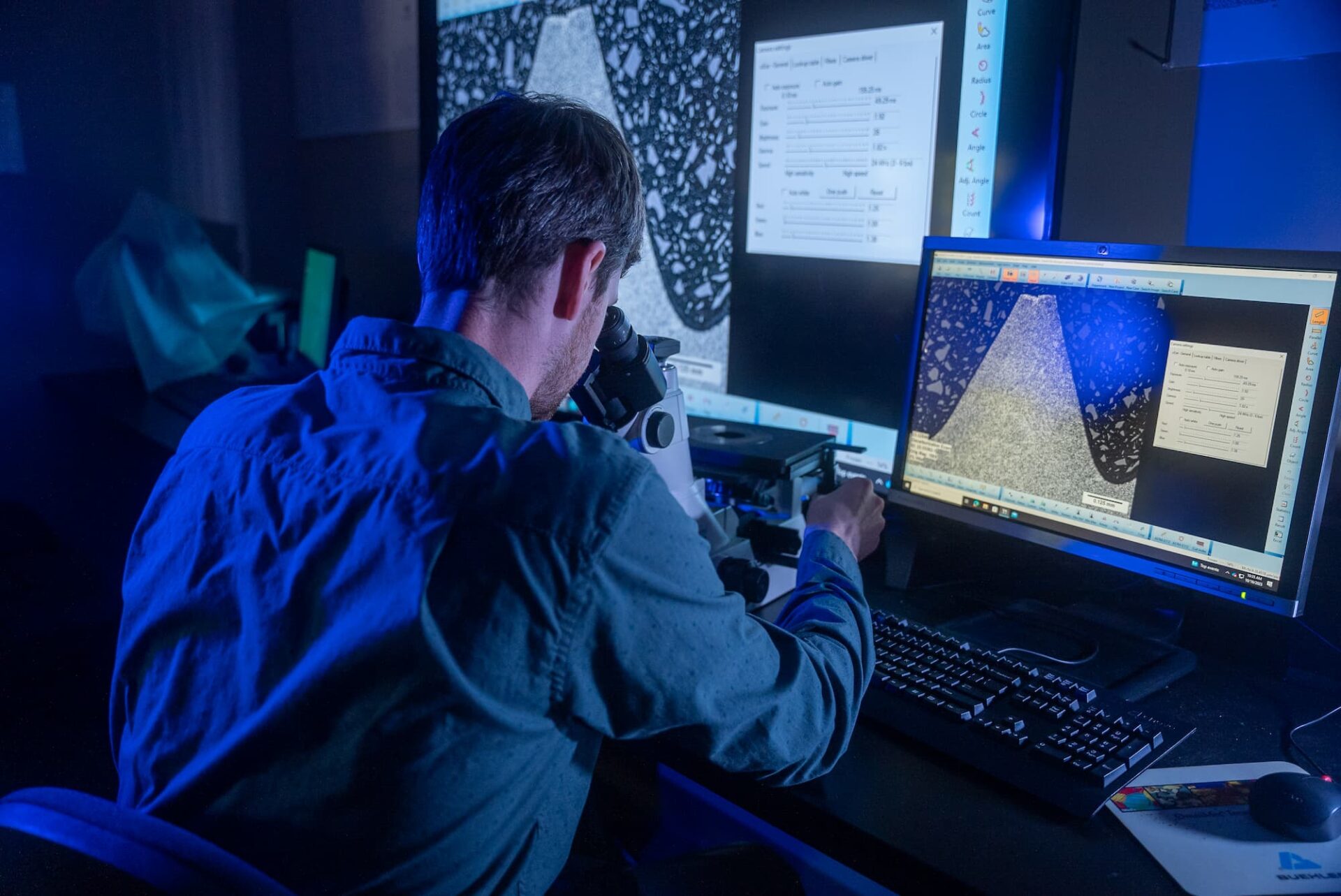

Material failure always has its roots at the microscopic level, where tiny interactions between grains ultimately establish the macro-level performance. These interactions are evident during microscopic examination of metals, where the aggregate work of manufacturing processes creates defects at the surface that can result in reduced performance or failure. For this reason, microscopic examination is necessary for any metal characterization, as it provides a detailed detection of present microstructures.

Microscopic Examination of Metals

Capabilities

Specifications

LTI’s Material Lab Testing Is an Industry-Leader

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.