Often, evaluating a prepared sample requires a chemical change to detect some identifying signature of the elements present. Inductively coupled plasma uses electromagnetic induction to furnish electrical currents that heat, vaporize, and ionize the sample to measure its mass-to-charge ratio against known values. Regardless of the spectroscopy mode, ICP analysis is a valuable tool for its speed, precision, and wide range of applicability.

Elements Measured* During an ICP Test Scan

ICP Analysis for AES and MS

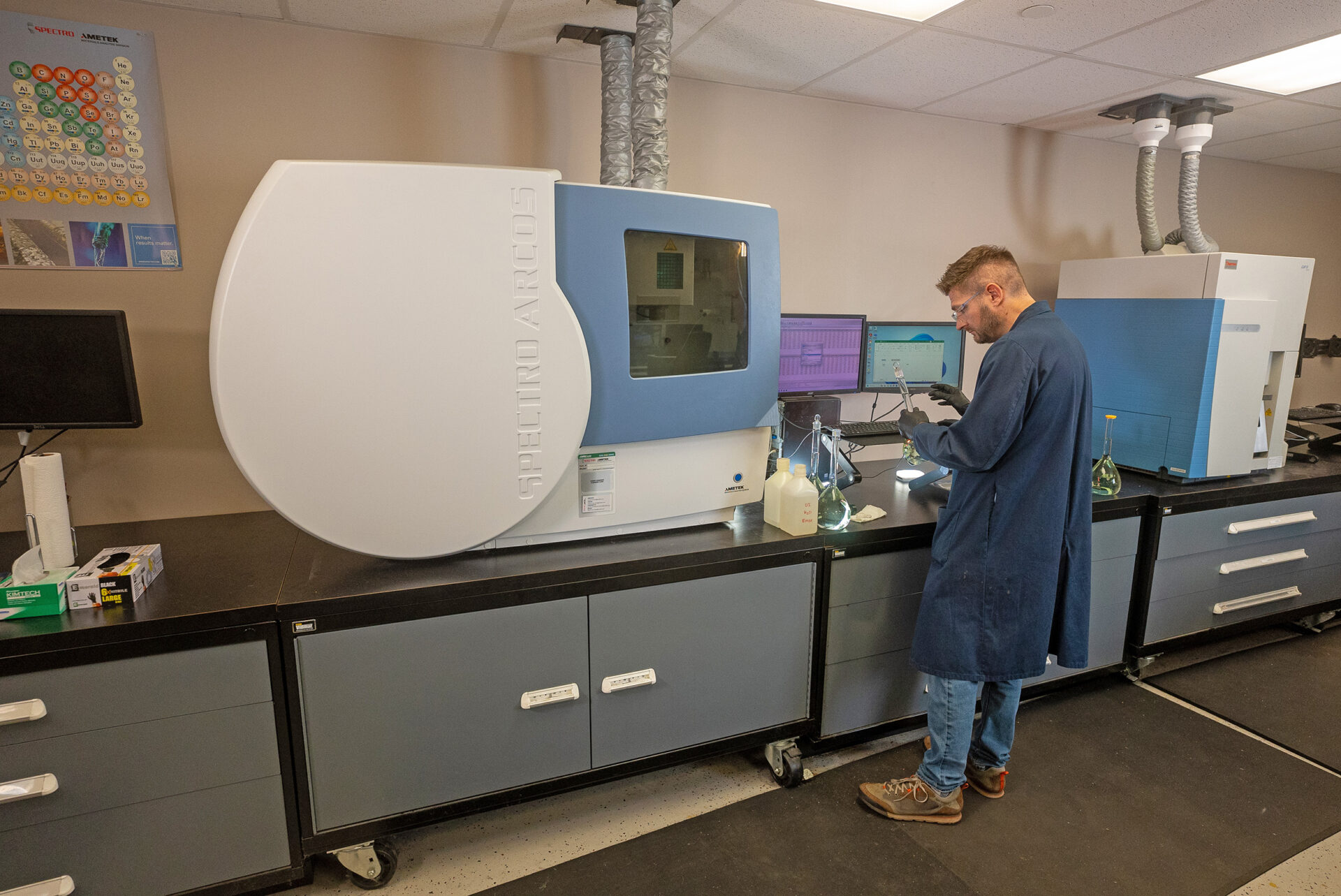

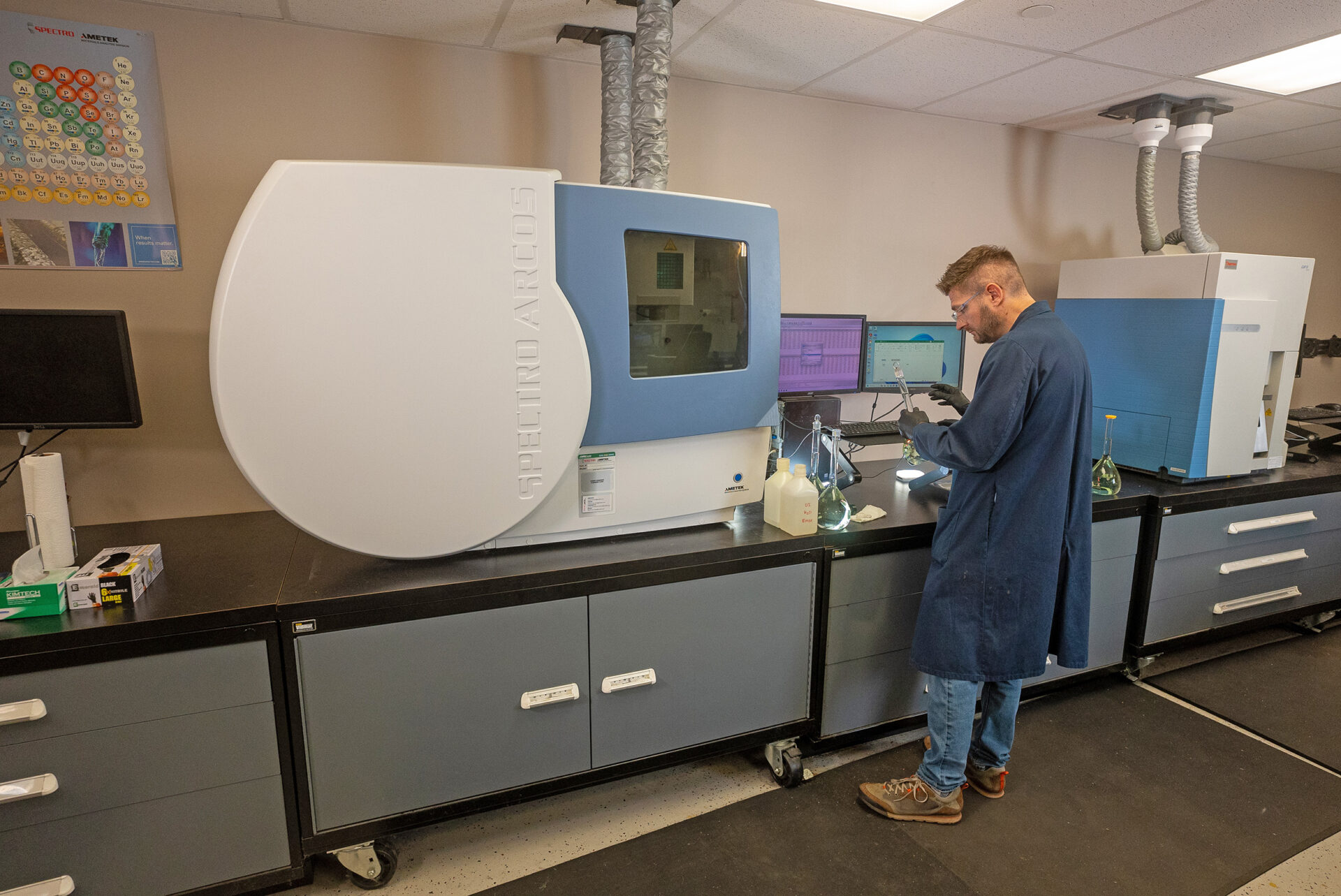

ICP analysis, also known as ICP testing, identifies and measures a range of chemical elements necessary to analyze metal and material samples. ICP-AES analysis and ICP-MS analysis services are available at our facility. Either of these ICP test methods is suitable for solid or liquid samples. They calculate quantitative and qualitative data for summarization in an ICP test report.

ICP-AES Analysis

Inductively coupled plasma atomic emission spectroscopy (ICP-AES) or ICP atomic emission spectroscopy is a technique that can determine concentrations of trace to major elements and detect most elements in the periodic table. Reliable results are attainable for about 70 elements with detection limits in the parts per billion range. This method is also known as ICP optical emission spectroscopy (ICP-OES).

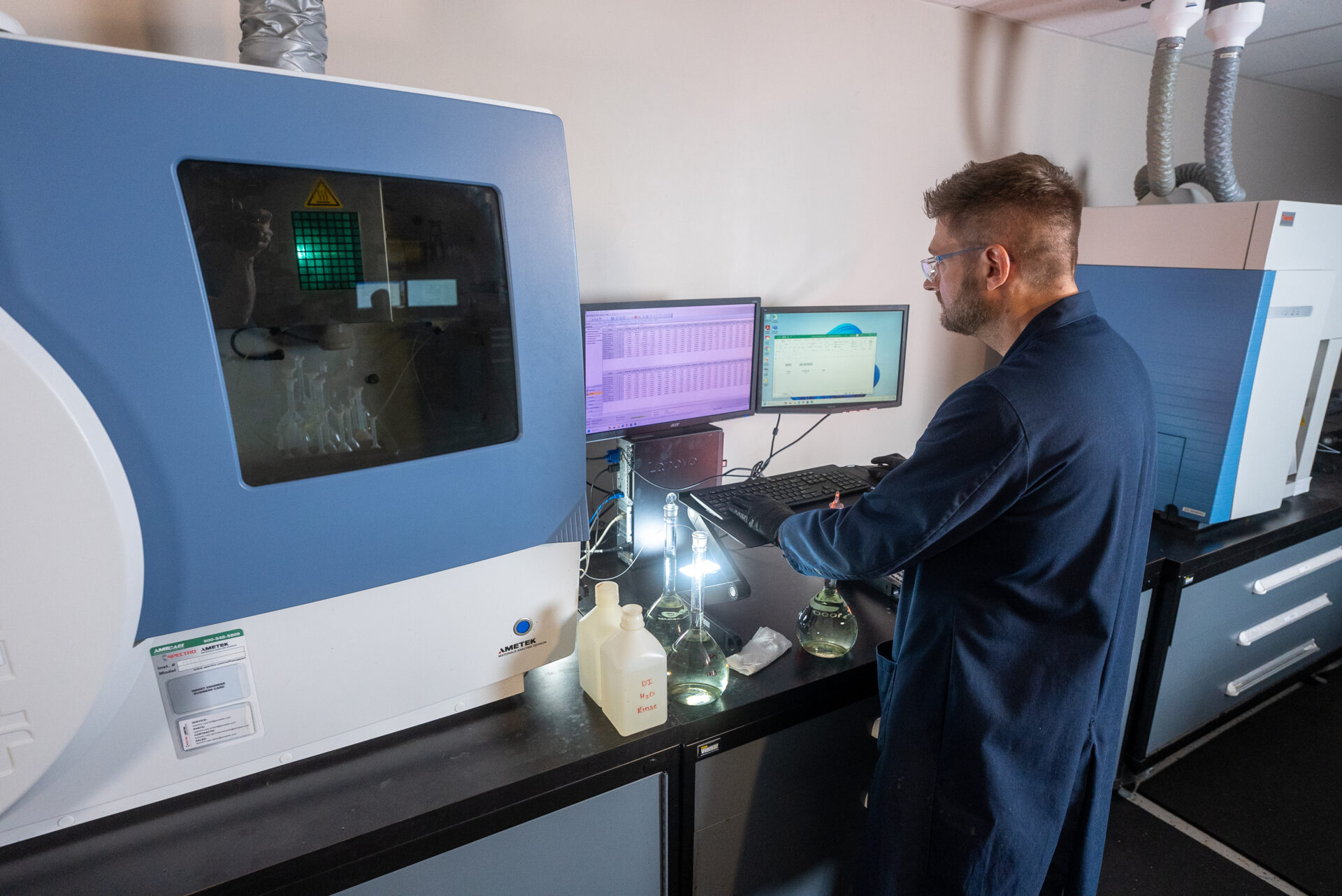

The ICP is an excitation source for atomic emission spectroscopy. The plasma consists of argon gas operated at atmospheric pressure and inductively coupled to a radio frequency (RF) electromagnetic field. The spectrometer detects the atomic emissions produced, while a computer controls and monitors instrument functions to process, store, and output the analysis results.

ICP Analysis Specifications and Capabilities

ICP-MS Analysis

Inductively coupled plasma mass spectrometry (ICP-MS) combines the easy sample introduction and quick analysis of ICP technology with the accurate and low detection limits of a mass spectrometer. This ICP analysis method exhibits high sensitivity and can perform multi-element analysis, often at the parts-per-trillion level. It is capable of the determination of a range of metals and several non-metals.

Samples are decomposed to neutral elements in a high-temperature argon plasma to produce ions and are analyzed based on their mass-to-charge ratios. Aqueous samples form by way of a nebulizer which aspirates the sample with high-velocity argon, forming a fine mist. The aerosol then passes into a spray chamber for removal. Droplets small enough to vaporize in the plasma torch pass into the torch body, where the aerosol mixes with more argon gas. A coupling coil transmits a radio frequency to the heated argon gas, producing an argon plasma at the torch. The hot plasma removes any remaining solvent and causes sample atomization followed by ionization.

We’ve enhanced our trace elemental analysis capabilities by adding a high-resolution inductively coupled plasma (ICP) quadrupole mass spectrometer for ICP-MS. The mass spectrometer allows routine chemical testing for trace elements in superalloys. It provides ultra-trace elemental analysis for high-purity alloys like those in the semiconductor industry. The ICP-MS spectrometer increases the capacity for chemical elemental analysis of samples into the parts per trillion range.

General ICP Test Processes

LTI performs both types of ICP analysis with computer-controlled spectrometers. Computer software controls and monitors the instrument functions, then processes and stores data before outputting the results of the ICP test. The spectrometers use charge-coupled device (CCD) technology, allowing the instruments to measure the broad spectrum of elements.

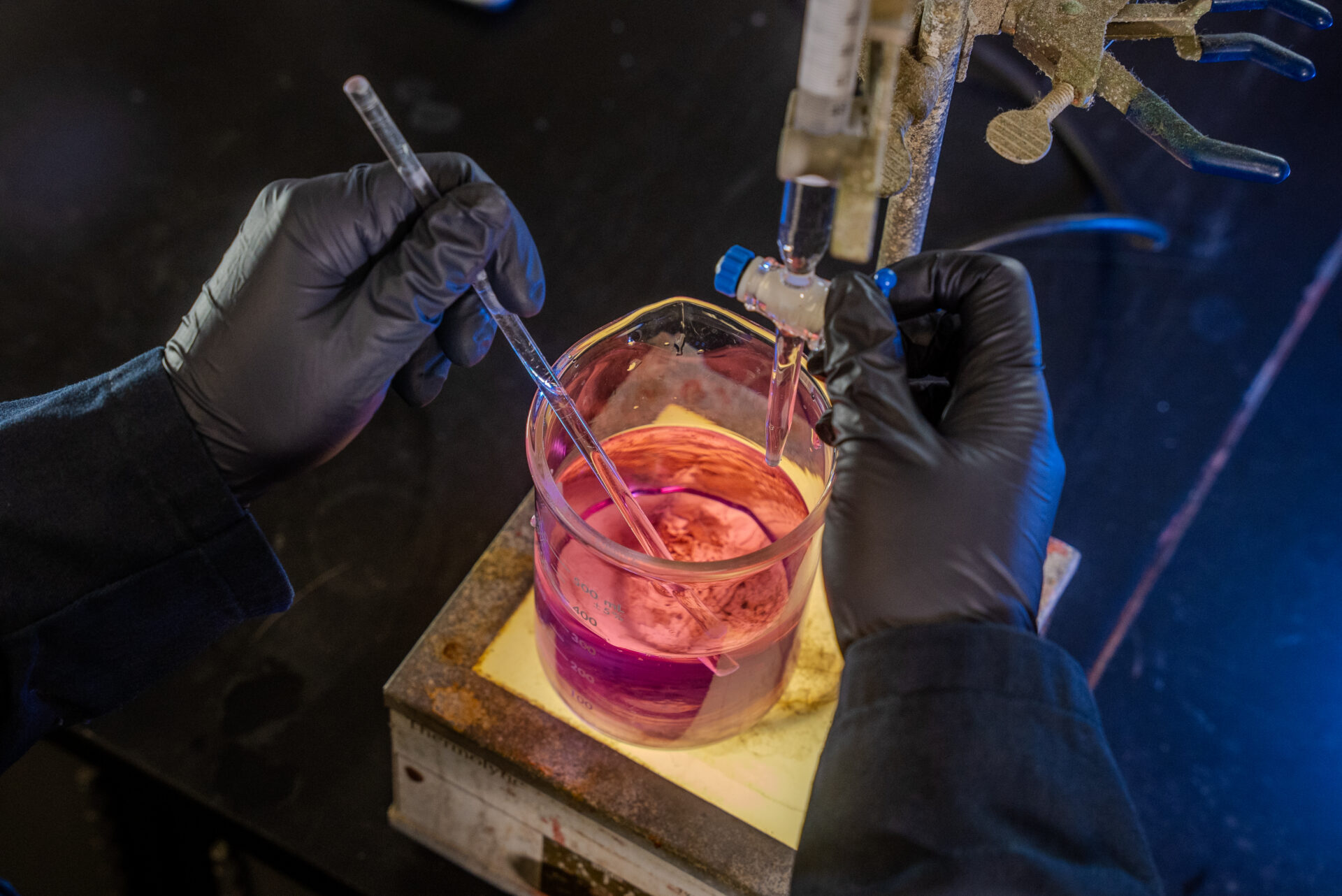

ICP metal analysis is performable on solid and liquid samples. However, a solid sample must be converted to liquid form before testing by dissolving the sample in a solvent (typically acid) to produce a solution. The sample solution enters the ICP as a fine aerosol of droplets—the aerosol forms from a nebulizer which aspirates the sample with high-velocity argon to form a fine mist.

The aerosol then passes into a spray chamber to remove larger droplets. Droplets small enough to be vaporized in the plasma torch pass into the torch body, where the aerosol mixes with more argon gas. A coupling coil transmits a radio frequency to the heated argon gas, producing an argon plasma in the torch. The hot plasma dries any remaining solvent and causes sample atomization.

The ICP-AES spectrometer detects the atomic emissions produced as light. With ICP mass spectrometry, the process uses ionization. The resulting mass of the ions indicates the elements present in the sample.

ICP Analysis Methods are But a Couple Of Our Services

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.