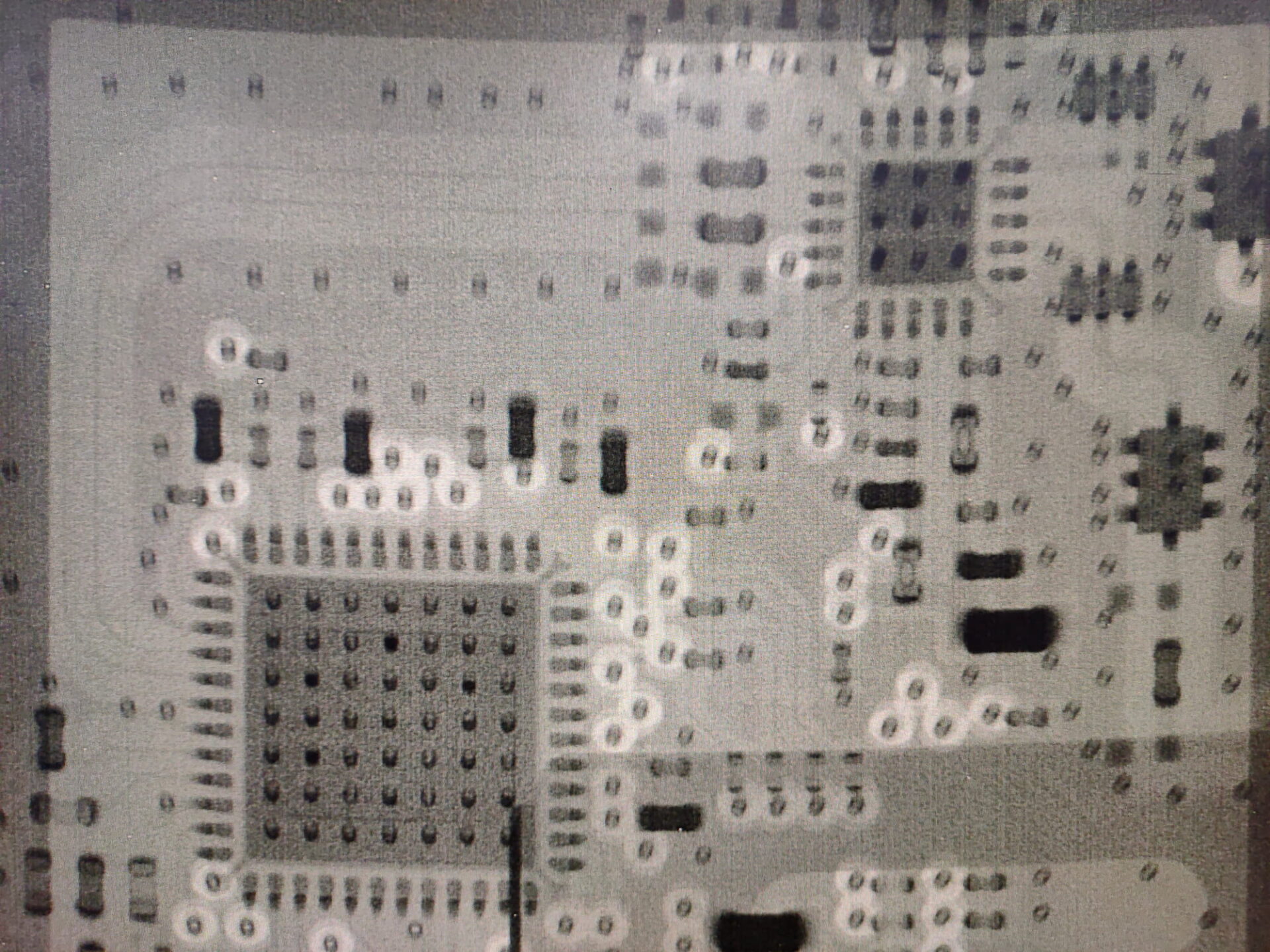

A Quality Magazine article by Jason Tucker entitled “Inspecting Plastics and Electronics With Conventional X-Ray” explains that industrial radiography is no longer primarily a metal inspection process. There is a growing demand for radiographic or x-ray inspection from manufacturers and buyers who want information about flaws and features below the surface.

The article discusses the value of using radiographic inspection to look for irregularities in plastic, silicone, and rubber products, as well as in electronic components. Jason mentions unique uses for this inspection method, including inspecting paintings for hidden documents and studying underpainting layers for museum curators and archivists. This method is also helpful in analyzing damaged components during fire investigations to determine the cause of the fire.

Reliable Product Verification

Radiographic inspection is a nondestructive testing method that provides valuable information and quality assurance without compromising the integrity of the test piece. Manufacturers and buyers in the medical, aerospace, defense, and other industries rely on X-ray inspection for verification.

In his article, Jason explains that two types of industrial radiography are available: Computed Radiography (CR) with digital results and Conventional Radiography (XR) using film. Both methods are offered by the X-ray Inspection Department at Laboratory Testing Inc. and have been used to inspect a range of samples made of metals, polymers, and more.

X-Ray Inspection Options With LTI

Products and raw materials of varying shapes and sizes are inspected at LTI, including tubing, pipe, castings, weld plates, injection molding, circuit boards, and batteries. Industrial radiography is performed to MIL and ASTM specifications, and certified NDT Level II and Level III technicians evaluate the digital and film images. The results of the inspection are provided to clients in Certified Test Reports.

Related Articles

Introduction to the ASTM E606 Standard

Low-Cycle Fatigue Testing and the Standards Set Forth by ASTM In the world of engineering, materials are often subjected to…

The Top 5 Consequences of Industrial Operations Not Calibrating Their Equipment

In the fast-paced world of industrial operations, precision is not just a goal—it’s a necessity. Calibration of equipment, a process…

The Benefits of Choosing a Calibration Company that Offers Instrument Replacement and Purchasing Services

In the demanding world of industrial manufacturing and quality assurance, selecting the right calibration partner can significantly impact your operational…

How Small a Defect Can UT Find

Customers often ask LTI how small a defect ultrasonic testing (UT) can find. This question is very difficult to answer…

Ethics in Laboratory Testing

What could be more important than ethics in the world of materials testing? Testing laboratories have an obligation to adhere…

Quality Considerations in Chemical Analysis

A Well-Planned and Managed Quality Control Program When you need chemical analysis services, you expect to receive accurate testing and…