Low-Cycle Fatigue Testing and the Standards Set Forth by ASTM

In the world of engineering, materials are often subjected to fluctuating or cyclic stresses during their operational life. These stresses can lead to fatigue, which is one of the most common causes of material failure. To predict how materials will behave under cyclic loading, the ASTM E606 standard provides a structured method for conducting low-cycle fatigue testing on metals and alloys. Specifically, it covers strain-controlled fatigue testing to determine the fatigue life of materials when they are subjected to cyclic strains that lead to eventual cracking or failure.

This blog will guide you through the basics of ASTM E606, focusing on the importance of fatigue testing, the role of test specimens, and the geometries recommended by the standard.

Overview of ASTM E606:

Strain-Controlled Fatigue Testing

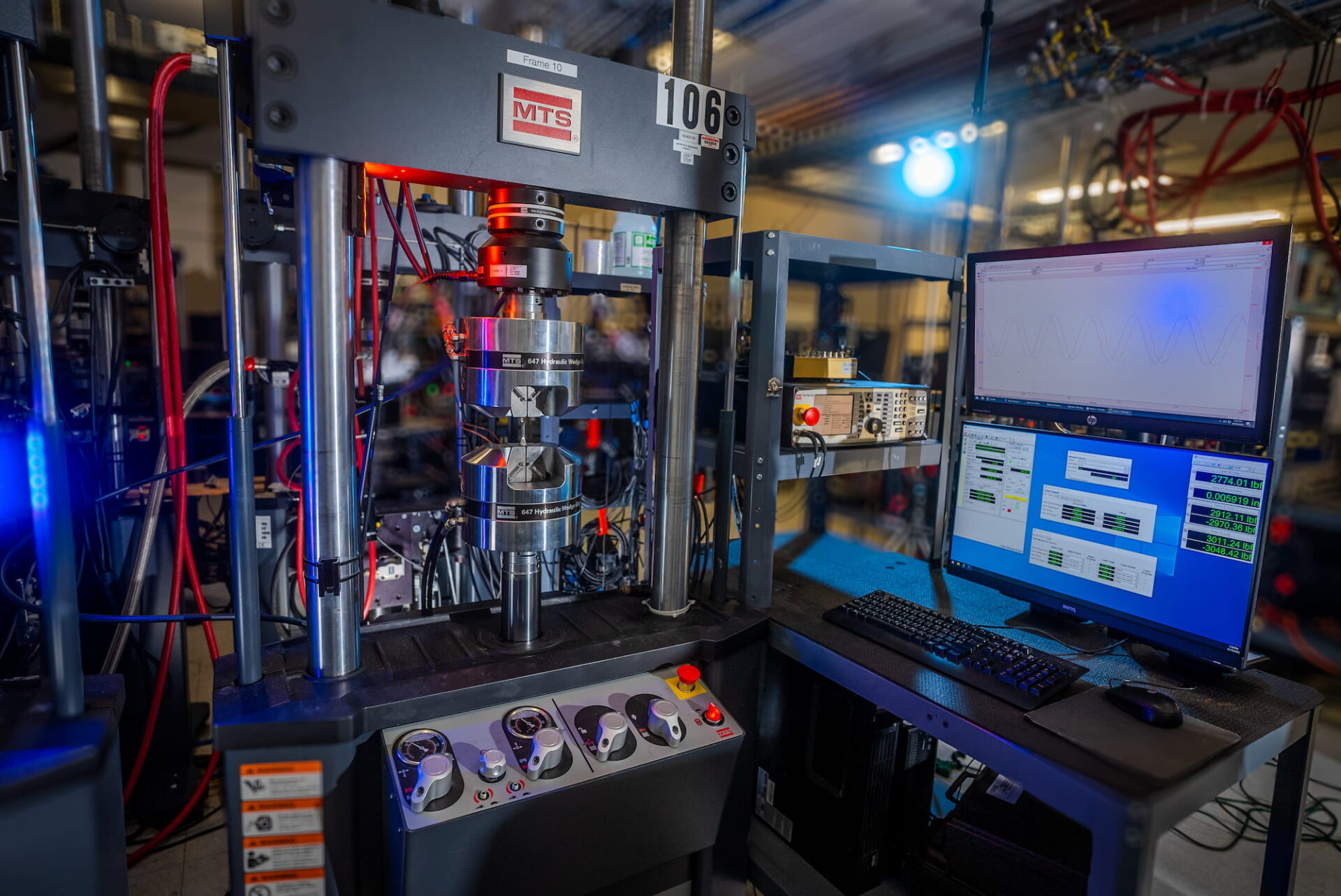

ASTM E606 is a comprehensive standard used to evaluate the fatigue behavior of metallic materials. The goal is to subject specimens to repeated strain cycles and observe the effects over time, such as crack initiation and propagation. Fatigue data gathered using this method can help engineers predict how materials will perform in real-world conditions.

Key Elements of ASTM E606 Testing:

- Strain-Controlled Cyclic Loading: The material is subjected to cyclic loading based on controlled strain levels, allowing researchers to observe how materials respond to deformation.

- Cyclic Stress-Strain Curve: This curve helps characterize the material’s fatigue properties, including the elastic and plastic response of the metal.

- Fatigue Life Estimation: The number of cycles to failure under varying strain amplitudes is recorded to determine the fatigue life of the material.

- Crack Initiation and Propagation: The testing allows for the analysis of crack formation in materials, which is critical in evaluating structural integrity.

The ASTM E606 testing is essential for industries like aerospace, automotive, and manufacturing, where materials are constantly exposed to cyclic stresses in harsh environments.

Predominant Industries Using ASTM E606:

1. Aerospace and Defense: Components like turbine blades, structural airframe parts, and landing gear are subjected to cyclic loads during operation. Fatigue resistance is critical to ensure the reliability and safety of these components.

2. Automotive: Vehicle components, especially in engines, suspensions, and chassis, experience cyclic stresses. Strain-controlled fatigue testing helps manufacturers assess the durability of materials and components over time under repeated loads.

3. Power Generation (Energy Sector): Components in power plants, such as turbines, boilers, and other high-stress parts, must withstand long-term operational fatigue. This includes both fossil-fuel and nuclear power plants.

4. Oil and Gas: Offshore platforms, pipelines, and drilling equipment undergo significant cyclic stresses due to environmental forces. Testing helps ensure these materials can handle prolonged operational conditions.

5. Construction and Civil Engineering: In bridges and large structures, materials experience cyclic loads from traffic, environmental conditions, and vibrations. Understanding the fatigue behavior of these materials is crucial for long-term durability.

6. Medical Devices: Implants and prosthetics, which are subjected to repeated stress and strain from the human body, also benefit from strain-controlled fatigue testing to ensure they can perform safely over an extended period.

7. Raw Material Suppliers: Producers of metals and alloys often perform fatigue testing to provide data on the fatigue properties of their materials to customers.

8. Additive Manufacturers: Additive Manufacturers often utilize fatigue testing to verify the integrity of 3D printed components used across numerous industries where failure is not an option.

Test Specimens in ASTM E606

One of the critical components of strain-controlled fatigue testing is the test specimen itself. The standard specifies detailed guidelines for the shape, size, and geometry of specimens to ensure consistency and reproducibility in testing results. The specimen’s geometry is particularly important since factors like shape and surface condition can influence the fatigue performance of a material.

The ASTM E606 provides various recommendations for specimen geometries, each designed to minimize inconsistencies in data collection and simulate real-world conditions effectively.

Basic Geometry Types

- Cylindrical Specimens:

Cylindrical specimens are among the most commonly used in ASTM E606 testing. They are designed to allow uniform stress distribution along the test length, ensuring accurate results. These specimens typically have a reduced section in the middle, where the testing forces are concentrated, while the ends are gripped securely in the testing apparatus.

Dimensions for a cylindrical specimen typically include:

- A reduced gauge section, where the cyclic strain is applied.

- A transition section to avoid stress concentration at the ends.

- A gripping section at both ends for mounting the specimen in the testing machine.

Applications: Cylindrical geometries are frequently used in aerospace and automotive industries for testing components like shafts, bolts, and pins that experience rotational or axial loading.

- Flat Specimens:

Flat specimens are another common type, often used for sheet metals or materials with directional grain structures. They typically have a rectangular cross-section with a reduced middle section. These specimens can simulate the behavior of thin materials that are subject to cyclic bending or tensile forces in real-world applications.

Dimensions for flat specimens include:

- A uniform reduced section where strain is focused.

- Tabs or grips on either end to secure the specimen in the test machine.

Applications: Flat specimens are useful for evaluating the fatigue life of thin components like metal plates, structural panels, and other flat geometries used in various industries.

- Notched Specimens:

Notched specimens are specially designed to introduce stress concentrations into the material. These specimens simulate real-world conditions where cracks or flaws may exist in the material, which can significantly impact fatigue life. Notches can take the form of sharp grooves, holes, or other geometric features.

Notched specimen dimensions:

- Similar to flat or cylindrical specimens, with the addition of a machined notch or defect in the reduced section.

Applications: These specimens are often used in critical structural components where stress concentrations (such as bolt holes or sharp corners) may initiate cracks, such as in aircraft fuselages or automotive frames.

Geometric Considerations in ASTM E606

The geometry of a test specimen is crucial to ensuring accurate, reproducible results. Several factors need to be taken into account:

- Gauge Length: The reduced section of the specimen where strain is applied is critical for ensuring that the material deforms uniformly and predictably. The gauge length is typically minimized to focus the cyclic stresses in a small, controlled area.

- Surface Finish: A rough or uneven surface finish can introduce stress concentrations that may artificially shorten the fatigue life of a specimen. For this reason, ASTM E606 recommends a polished surface finish to eliminate irregularities that could skew results.

- Stress Concentration and Notches: As previously mentioned, notches or other stress concentrators can be introduced intentionally to simulate real-world conditions. These geometric modifications allow for the testing of how materials behave when flaws are present, helping engineers better predict material performance in practice.

- Gripping Sections: These sections ensure that the specimen is securely held during testing, without affecting the strain applied to the reduced section. Care must be taken to ensure the gripping sections do not introduce additional stress that could interfere with the results.

Conclusion

ASTM E606 provides a robust framework for evaluating the fatigue life of metallic materials under cyclic strain. The standard ensures that the test conditions are repeatable and consistent, offering critical data for industries where fatigue failure is a major concern. Understanding the geometric requirements of test specimens is essential for producing reliable results. Whether using cylindrical, flat, or notched specimens, the specific geometry of the specimen will influence how a material performs under cyclic loading, and by following the guidelines set out in ASTM E606, engineers can simulate real-world operating conditions and better predict material performance.

This standard plays a crucial role in ensuring the safety and longevity of components that experience fluctuating stresses, making it indispensable in sectors like aerospace, automotive, and heavy machinery manufacturing. By understanding both the basics of the standard and the nuances of specimen geometries, one can better appreciate the importance of fatigue testing in material science and engineering.

Related Articles

The Top 5 Consequences of Industrial Operations Not Calibrating Their Equipment

In the fast-paced world of industrial operations, precision is not just a goal—it’s a necessity. Calibration of equipment, a process…

The Benefits of Choosing a Calibration Company that Offers Instrument Replacement and Purchasing Services

In the demanding world of industrial manufacturing and quality assurance, selecting the right calibration partner can significantly impact your operational…

How Small a Defect Can UT Find

Customers often ask LTI how small a defect ultrasonic testing (UT) can find. This question is very difficult to answer…

Ethics in Laboratory Testing

What could be more important than ethics in the world of materials testing? Testing laboratories have an obligation to adhere…

Quality Considerations in Chemical Analysis

A Well-Planned and Managed Quality Control Program When you need chemical analysis services, you expect to receive accurate testing and…

Spectroscopy Explained

In our new article titled “Spectroscopy Explained”, you’ll learn how chemical testing is performed to answer many questions about material…