Laboratory Testing Inc. provides computed and film radiography inspection services through its Nondestructive Testing (NDT) Department, which performs ultrasonic testing, hydrostatic pressure testing, magnetic particle inspection, liquid penetrant testing, and visual inspection. These nondestructive testing services are PRI/Nadcap accredited and are performed according to strict quality procedures to ensure reliable results. LTI’s nondestructive testing technicians are certified to ASNT SNT-TC-1A, NAS410/MIL-STD-410, MIL-STD-2132, and Pratt & Whitney PWA-NDTQ. Certified NDT Level II and Level III technicians evaluate all test results.

LTI Radiography Capabilities

Test Summary

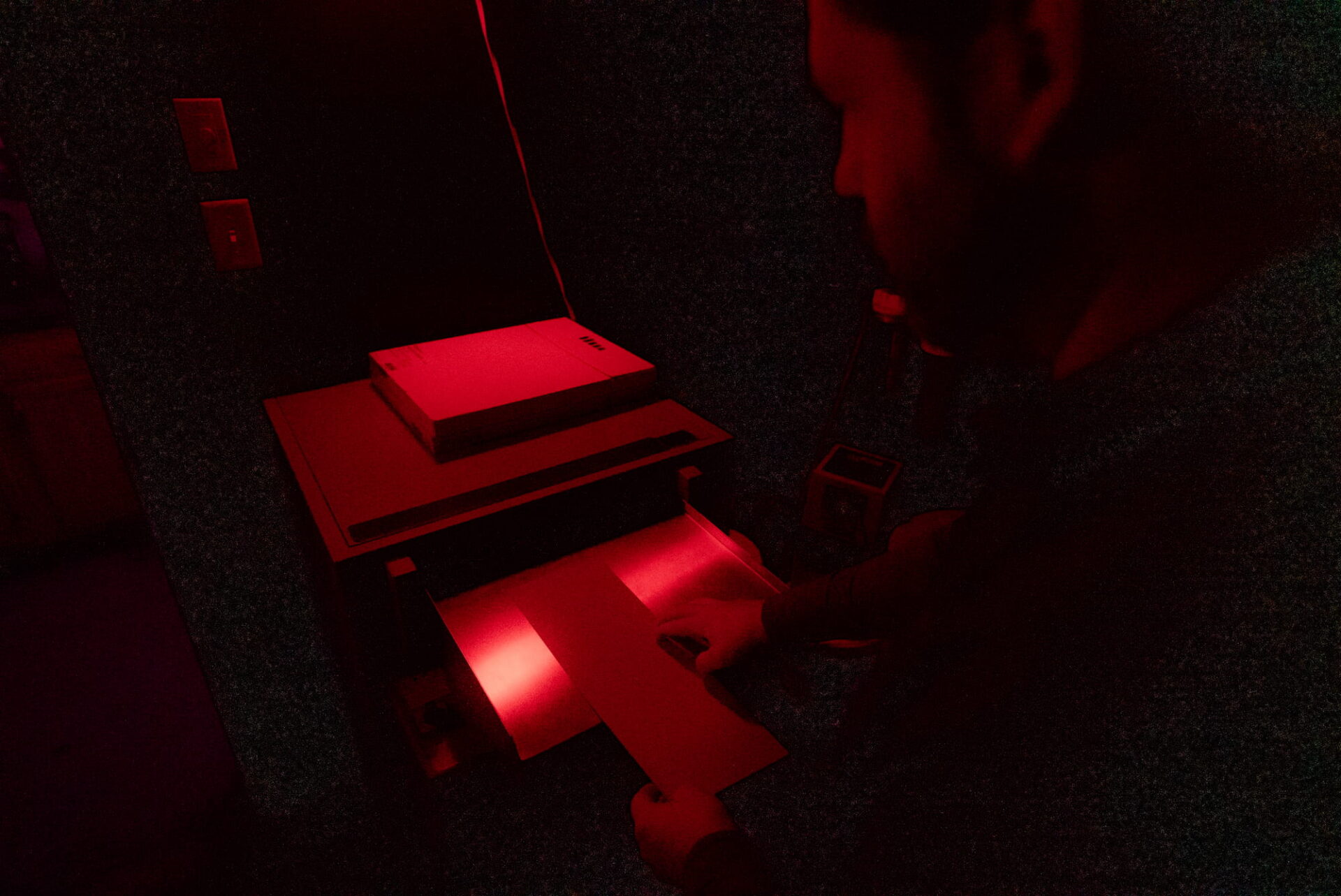

- Processes – Computed radiography (digital) and conventional radiography (film)

- Products Tested – Solid materials

- Size Limitations – Small (cabinet radiography) to large (20 x 20 ft. room)

- Material Thickness – X-ray equipment can penetrate varying thicknesses

Standards

- ASME

- ASTM E94

- ASTM E1030

- ASTM E1742

- MIL-STD-271

- MIL-STD-453

- NAV-C

- PED

Radiography Inspection Services at LTI

Radiography Uses

Defect Detection

Industrial X-ray inspection of solid materials and products, also called industrial radiography or radiographic testing (RT), is a very effective method of uncovering subsurface defects. Laboratory Testing Inc. offers two types of industrial radiography to meet industry standards, specifications, and customer preferences.

X-Ray Inspection

X-ray inspection can reveal hidden voids and defects in various solid materials, including metal, plastic, composites, silicone, and rubber. Radiography is a nondestructive testing (NDT) method and will not harm the test piece. The processes and imaging equipment used to perform both conventional and computed radiography are similar, yet their output differs – each with its advantages.

Take A Closer Look With LTI’s X-Ray Services

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.