Testing Experience to Understand Your Company

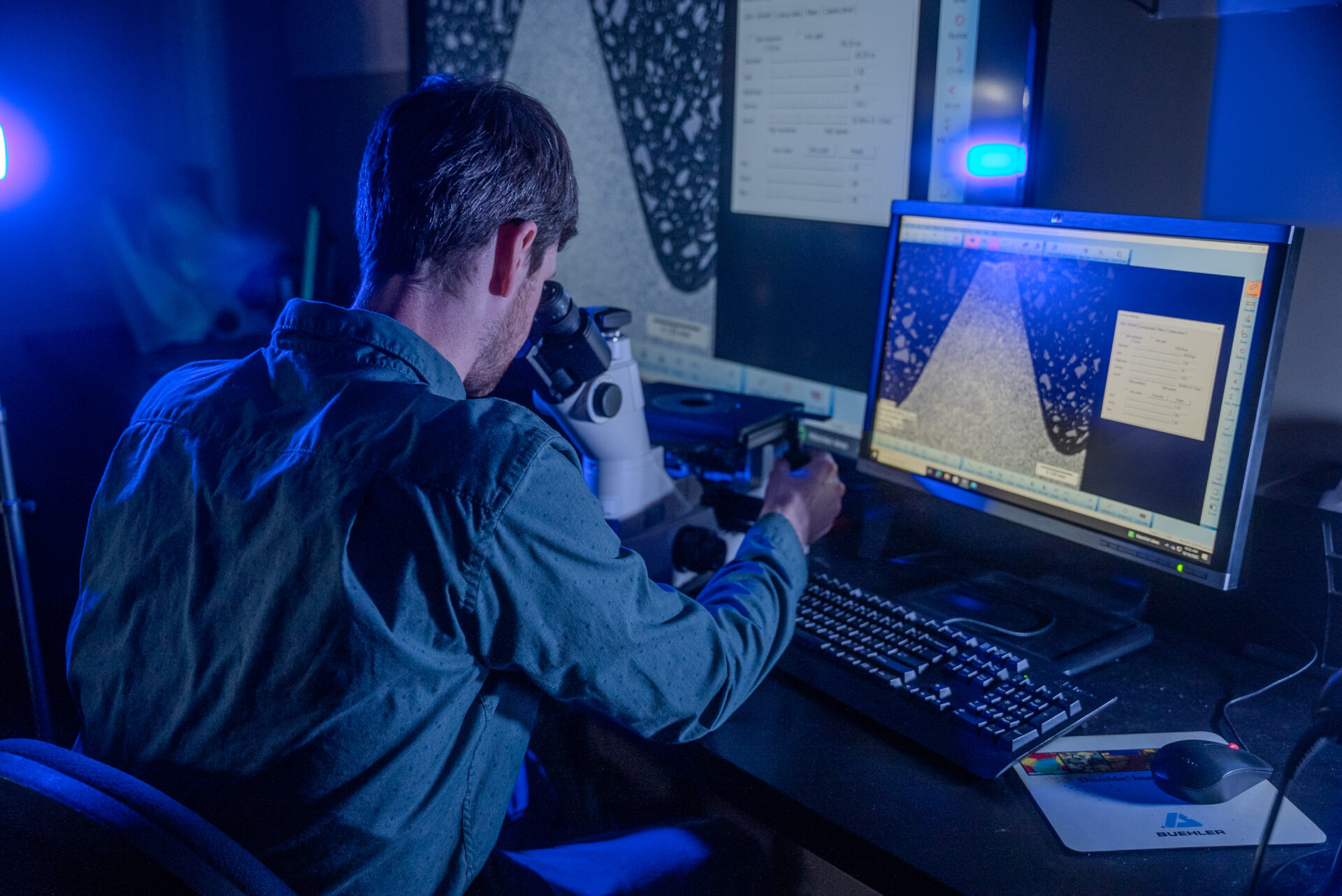

Laboratory Testing Inc.’s unwavering commitment to customer satisfaction revolves around prioritizing your unique needs within mission-critical industries and customer types. We’ve developed tailored service solutions to address your company’s distinct requirements. Our unwavering dedication to customer service means we put your needs first regarding industrial testing services. We excel in helping customers navigate and meet challenging deadlines and requirements, delivering exceptional service, technical expertise, reliable accuracy, and timely turnarounds.

LTI’s accredited and industry-approved materials testing lab provides key support services to original equipment manufacturers (OEMs) and suppliers. Our material testing lab services are ideally suited to serve the destructive testing, nondestructive testing, and calibration requirements across a broad spectrum of industries, and the services are all performed under one roof.

Material Testing for Our Customer Types:

Original Equipment Manufacturers (OEMs)

Manufacturing is a difficult task requiring industrial equipment, expertise, and the maintenance and training to accompany each. Even at the early stages of design, product development must regard the limits of manufacturing tolerance and how to translate design intent cost-effectively. LTI partners with OEMs to assist in material selection alongside material research to push manufacturing capabilities forward.

Metal Mills

Precision and quality are essential for ensuring product integrity and performance in the metal mill industry. LTI specializes in advanced testing solutions, including ultrasonic testing and mechanical testing, to support the highest quality control standards and product reliability. Understanding a test lab’s pivotal role in the production cycle, we recognize that time is critical for metal mills to meet their goals efficiently and with unwavering quality.

Forgers

Forging is a high-heat and pressure mechanism for producing metals in various shapes, and the material properties of both the metals and those imparted by the processes combine to form the final product. Mechanical, metallographic, and chemical testing is necessary to ensure compliance.

Fasteners

Identifying weaknesses or defects before costly problems occur (and while corrections are still possible) is critical. Laboratory Testing Inc. offers a broad range of dimensional inspection and testing capabilities.

Additive Manufacturers

In additive manufacturing, precision, and quality are of utmost importance in the additive manufacturing market. LTI is an essential partner for clients in this dynamic industry, including manufacturers and innovators at the forefront of 3D printing and additive manufacturing technologies. We play a pivotal role in ensuring the quality and integrity of materials and components used in this cutting-edge field, offering a range of testing services that encompass both Destructive and Non-Destructive Testing techniques.

Fabricating and Manufacturers

For the fabricating and manufacturing industries, LTI brings extensive expertise and capabilities, particularly in weld qualification. Our materials and non-destructive testing (NDT) labs provide comprehensive solutions for material identification, selection, conformance certification, process verification, and performance evaluation.

Heat Treating

In the heat treating industry, precision and efficiency are paramount. LTI offers fast turnaround times and a customer portal for immediate results and historical reports, enhancing transparency and ensuring your operations run smoothly.

Serving Mission-Critical Industries:

Aerospace and Space

LTI serves the aerospace sector, including OEMs and critical suppliers, where precision is paramount. Our project engineers and program management experts collaborate with industry leaders to uphold the highest quality material procurement and development standards—experience excellence in complex material characterization projects, driven by our unmatched expertise and cutting-edge testing solutions.

Power Generation

In the nuclear and power generation sector, safety and reliability are non-negotiable. LTI plays a crucial role, offering comprehensive Destructive and Non-Destructive Testing services. Power-generating plants rely on us for meticulous inspection and in-depth material analysis to ensure their operations’ utmost safety and reliability.

Military / Defense

In the military and defense sectors, where precision and reliability are vital, LTI is a trusted partner for defense contractors and military original equipment manufacturers (OEMs). Our core role involves extensive Destructive and Non-Destructive Testing expertise bolstered by a robust quality program. This experience guarantees materials and components used in defense and military applications meet the strictest performance and safety standards.

Medical

The medical field is rapidly evolving, with new technological breakthroughs and improvements to medical materials, devices, and implants. What doesn’t change is the need for the highest quality and most reliable products. Laboratory Testing assures you that the materials going into your products will hold up to expectations.

Automotive / Transportation

Laboratory Testing is committed to helping the transportation industry provide its customers with the most reliable vehicles. We have assembled a wide array of testing and calibration services, state-of-the-art equipment, and experts in the field to ensure your company is working with quality materials and accurate measuring instruments.

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.