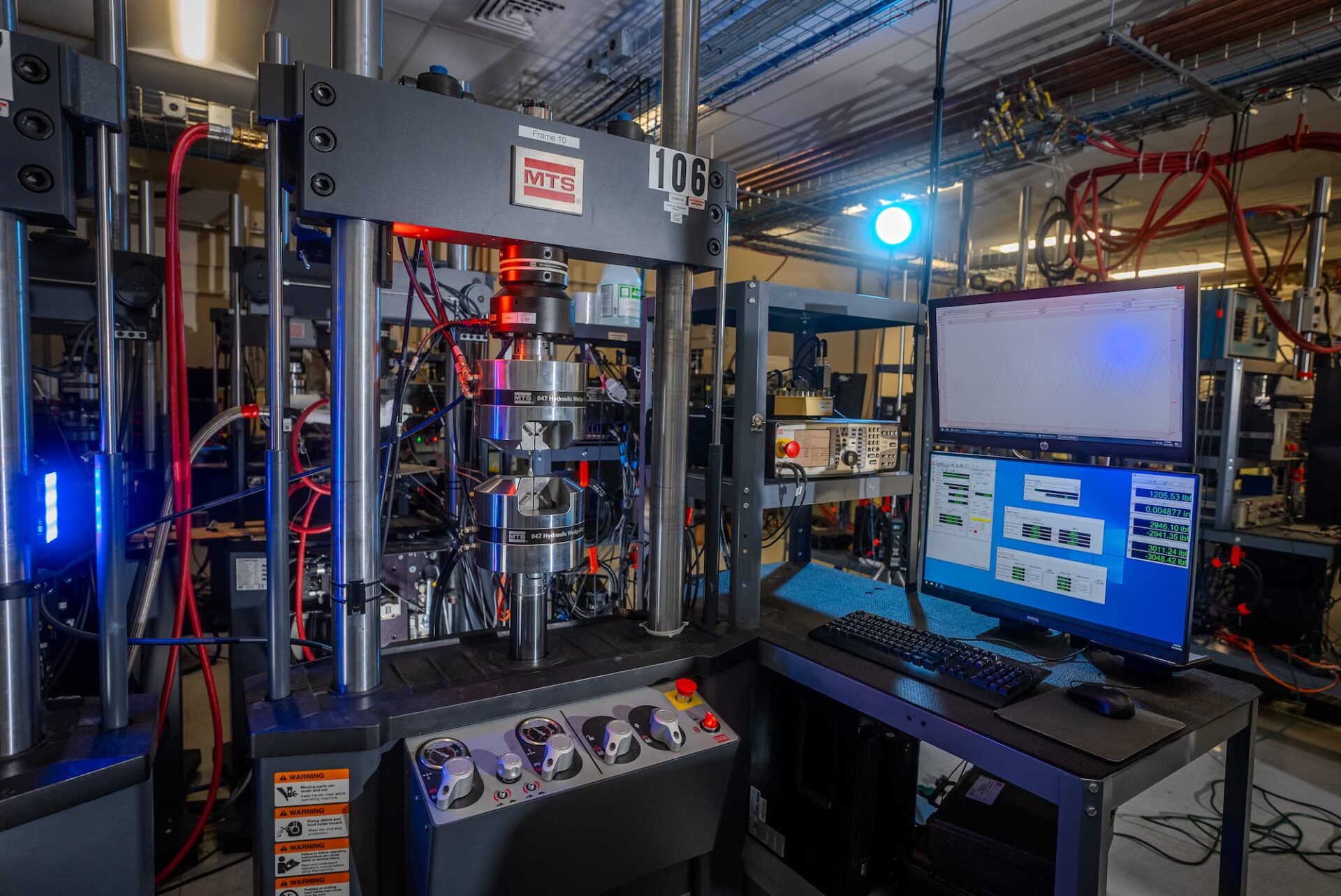

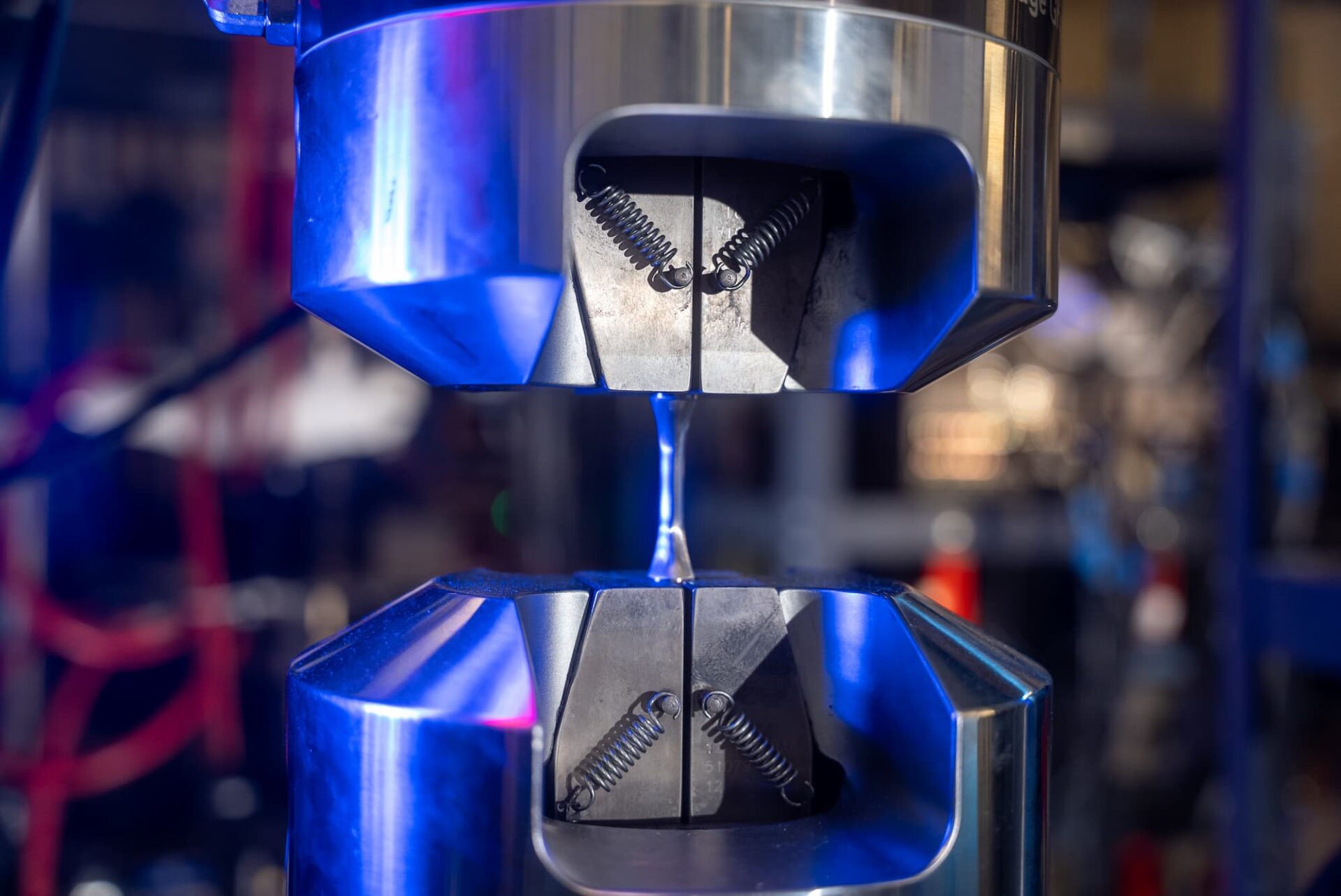

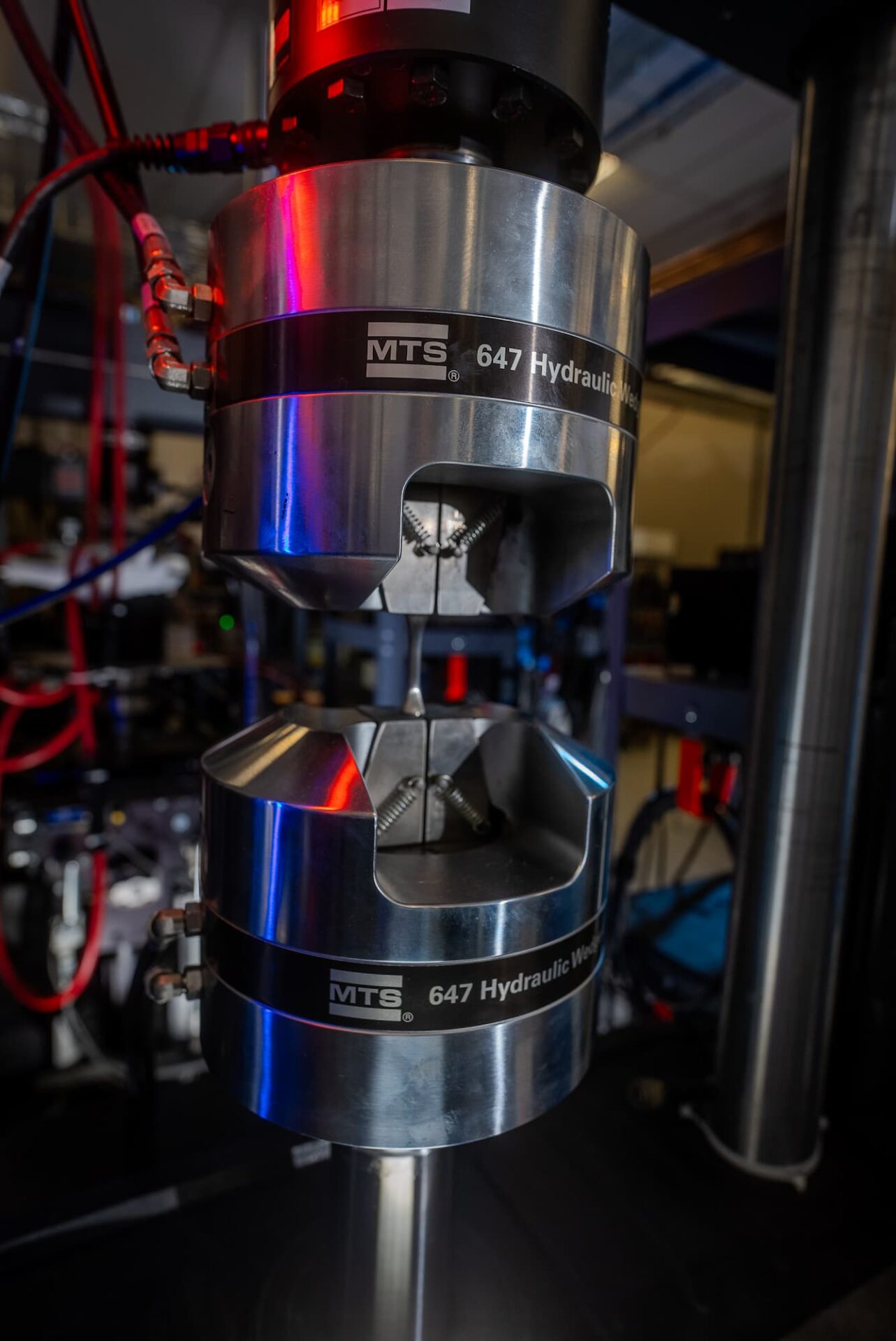

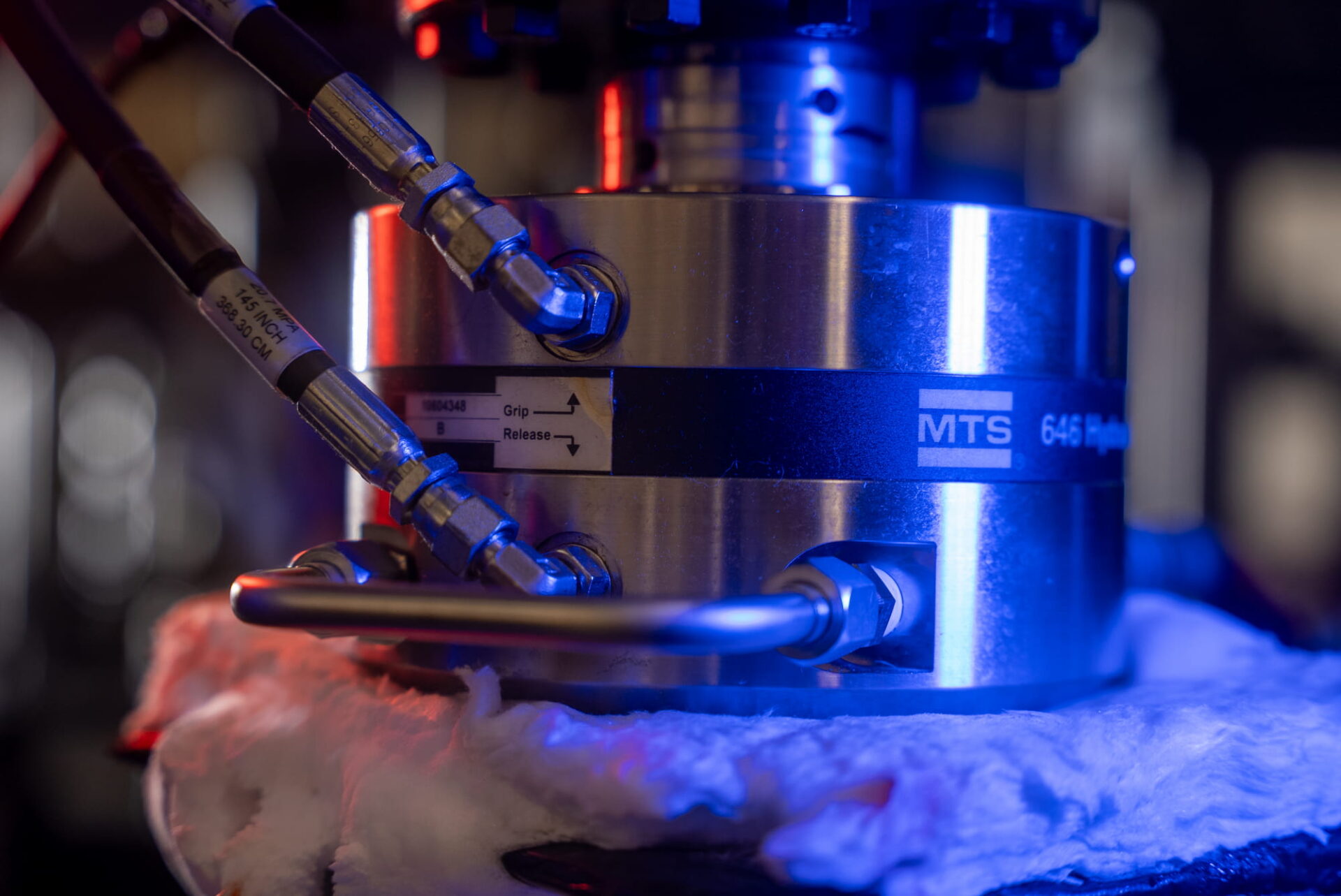

High Cycle and Low Cycle Fatigue Testing

Material properties are varied, and their test formats and styles must be as well to capture all the necessary data adequately. Fatigue testing laboratories require equipment and technical knowledge to simulate real-world wear in a compact timeframe. At LTI, our test departments are industry leaders in developing standards, and we bring this mentality to your products and test materials.

LTI has a full-service machine shop that supports low-stress grinding and polishing with various OEM approvals. We also have the support of our Metallography lab, which can run Fractography on fatigued samples.

Fatigue Testing Labs Analyze Materials Destructively

Fatigue Testing Process |

High- and Low-Cycle Fatigue |

| The fatigue testing experts at LTI understand the critical applications for high- and low-cycle fatigue test methods. Our state-of-the-art facility takes on critical material fatigue testing programs for aerospace (space, commercial, and military), defense, transportation, energy, and education. Fatigue testing is often performed for production testing or during research and development stages when our customers develop material characterizations. | Low cycle fatigue and high cycle fatigue test processes measure the ability of materials to withstand the application of repeated load cycles. The tests run under varying loads, speeds, and temperatures. Both high and low-cycle fatigue testing use cyclic loading to evaluate the lifespan of materials subjected to fluctuating strain and stress conditions, which may result in cracking or fracture. These tests are valuable in ensuring product safety, especially in industries where failure is not an option and human life is at stake. |

Capabilities

Get Relief From Testing Logistics Fatigue With LTI

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.